Commercial vehicles

PC-12 on track for 2027

26 August 2025

04 December 2014

Assessing the performance of lubricants in vehicles running on biodiesel

Results from an extensive Infineum field trial explore the impact of biodiesel dilution on engine oils and reveal how the use of high quality lubricants is increasingly important to prevent engine issues arising from the use of biodiesel.

As biodiesel use increases a good understanding of itsimpact on the performance of engine oils is essential

As governments the world over strive to meet climate change commitments and reduce dependence on oil imports, the use of renewable energy is increasing. Biodiesel is part of the renewable fuels portfolio and, as mandates/incentives are more widely introduced, blend levels are continuing to increase.

In Europe for example EN 590 now allows up to 7% (B7) biodiesel to be blended into conventional diesel fuel. In the US B5 is generally accepted but, as indicated in this year’s Infineum Winter Diesel Fuel Quality Survey, fuels at B10 and above are increasingly available. In Asia biodiesel mandated levels range from B2 in Korea up to B10 in Indonesia.

The increased use of biodiesel, designed to help meet renewable targets, can impact the engine oil and vehicle hardware performance.

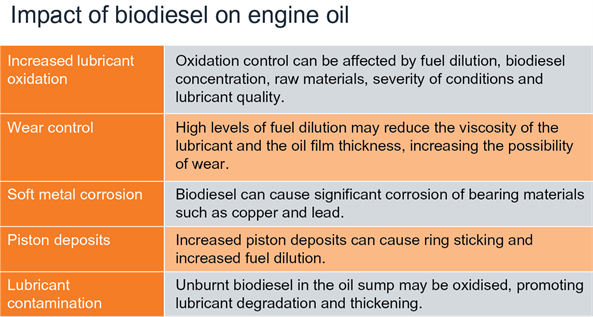

The primary concerns for the crankcase lubricant are the impacts biodiesel might have on engine cleanliness and the potential consequences of biodiesel contamination of the engine oil - known as fuel dilution. Evidence from previous work suggests biodiesel can affect the engine and oil in a number of ways.

The increased use of biodiesel and the move towards higher blend ratios has prompted Infineum to commit significant technology resource in order to gain a better understanding of the impact that biodiesel blends can have on the performance of engine oils.

Field trials in airport shuttle buses were designed todetermine the real-world impact of using B20

To determine the real-world impact of using B20 fuel Infineum designed a 100,000 mile field trial in medium-duty Las Vegas buses. In the trial, which lasted three and a half years, 25 buses plied the roads from the airport to local hotels testing the lubricants in a severe stop-go-idle drive cycle.

Four of the test oils were formulated with Infineum technology and one was a commercially available reference oil. For each of the test oils, four engines ran on B20 fuel and one on ultra low sulphur diesel fuel.

Oil levels were checked regularly and very high biodiesel dilution of 10-50% was observed.

Infineum identified a number of factors that could contribute to these high levels:

The excessive biodiesel dilution led to two revisions of drain interval for the field trial. The first, from the initially planned 10,000 miles to a point when the volume in the sump reached 1.9 litres over the full mark, and the second to one inch above the full mark on the dipstick.

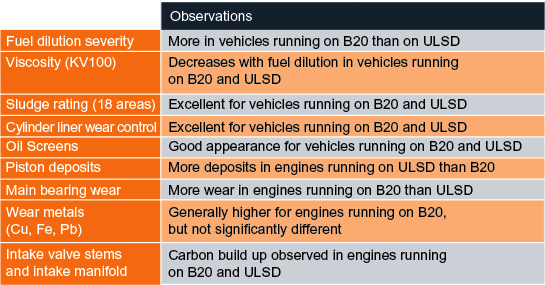

At the end of the trial all valve train regions were inspected, and all the engines showed an excellent sludge rating. All the engines also had excellent cylinder liner wear control and no problems with oil screens. As expected, across all vehicles, total acid number increased and total base number (TBN) decreased as the distance travelled lengthened.

Looking at fuel dilution against viscosity (KV100) demonstrated that viscosity decreased with increased fuel dilution. In addition engines running on B20 consistently showed more fuel dilution than those running on ULSD.

Across all five test oils viscosity decreased with increased fuel dilution Infineum International Limited

Metals analyses, which are indicative of wear, were consistently higher for the oils taken from vehicles running on biodiesel than on ULSD. In addition engines running on B20 showed consistently higher main bearing wear than those running on ULSD. But, there were less piston deposits in the engines running on biodiesel.

The OEM specification SAE 5W-30 oil had the lowest TBN throughout the test (reaching almost zero at the end of the test), which means it had less ability to neutralise acids. In addition the highest fuel dilutions were observed in this oil. In complete contrast, the API CJ-4 SAE 5W-30 oil had the highest TBN throughout the test and the least fuel dilution.

In most cases the engines running on B20 showed higher levels of iron, copper and lead in used oil analyses. Interestingly the API CJ-4 SAE 5W-30 and 15W-40 oils gave very similar trends to each other, which could indicate viscosity is not the main factor influencing these results.

While all engines running on B20 showed higher main bearing wear than the ULSD vehicle, the use of high quality oils can offset this fuel effect, as shown by the SAE 5W-30 CJ-4 oil and the SAE 10W-40 ACEA oil. Both the SAE 15W-40 oils, one formulated using Infineum technology and he other a commercial oil) showed higher levels of bearing wear, indicating that the quality of base oils used may attribute to higher wear. In addition, the SAE 5W-30 OEM specification oil showed poorer bearing ratings in both B20 and ULSD vehicles, suggesting that boundary lubrication is lost due to excessive fuel dilution – but despite this all the engines survived for the duration of the test.

The higher bearing wear observed in engines running on B20 can be offset by using high quality oils. Infineum International Limited

In our view, the most likely causes of the extreme dilution of the lubricant by the biodiesel were the design of the in-cylinder post injection for DPF regeneration combined with the severe stop-go-idle driving cycle. This fuel dilution had significant impacts on lubricant performance – specifically in terms of viscosity decrease and wear protection.

However, despite the severity of the stop/go/idle drive cycle in this field trial, all the test oils demonstrated the ability to provide adequate protection to these medium-duty bus engines running on B20 fuels over 100,000 miles. But it should be noted that careful attention must be paid to drain interval and used oil viscosity.

If the volume of biodiesel blended with conventional diesel continues to rise we can expect to encounter further crankcase lubricant formulation challenges. It is becoming increasingly important to use high quality oils tailored for specific biodiesel applications so that the higher levels of biodiesel can be tolerated as a diluent and to mitigate any negative effects derived from the fuel.

Sign up to receive monthly updates via email