Passenger cars

Roller coaster ride for US automakers

01 October 2025

28 August 2024

Porsche invests in electromobility and complementary e-fuels on the road to decarbonisation

To meet its ambitious decarbonisation goals, Porsche not only aims to sell more cars with an all-electric drive but also factors existing vehicles into its decarbonisation efforts. This means the company is looking for innovative ways to run internal combustion engines as close to net carbon neutral as possible. Infineum Industry Liaison Advisor, Frank Lauterwasser, explores how e-fuels, produced from electrolytic hydrogen, are a useful complement to Porsche’s electrification strategy that can form a viable part of a wider low-carbon transportation future.

Porsche says it aims to be net carbon neutral across the value chain for newly built cars by 2030. As part of its ambitious decarbonisation targets the company remains committed to electromobility, with plans for over 80% of new sales to be all electric drive by 2030. But, since it is renowned for building desirable and durable cars, it is also looking for ways to help existing vehicles run as close to net carbon neutral as possible. Porsche has invested heavily in HIF (highly innovative fuels), putting in over 100 million US dollars and significant effort to bring e-fuels to bear. It is now hoping to turn e-fuels into a viable solution that will enable nearly-carbon-neutral operation of internal combustion engines. This combination of electrification and e-fuels is what the company calls its ‘double e-strategy’.

Porsche says the potential of e-fuels is huge.

“There are currently more than 1.3 billion vehicles with combustion engines worldwide. Many of these will be on the roads for decades to come, and e-fuels offer the owners of existing cars a nearly carbon-neutral alternative.”

Source

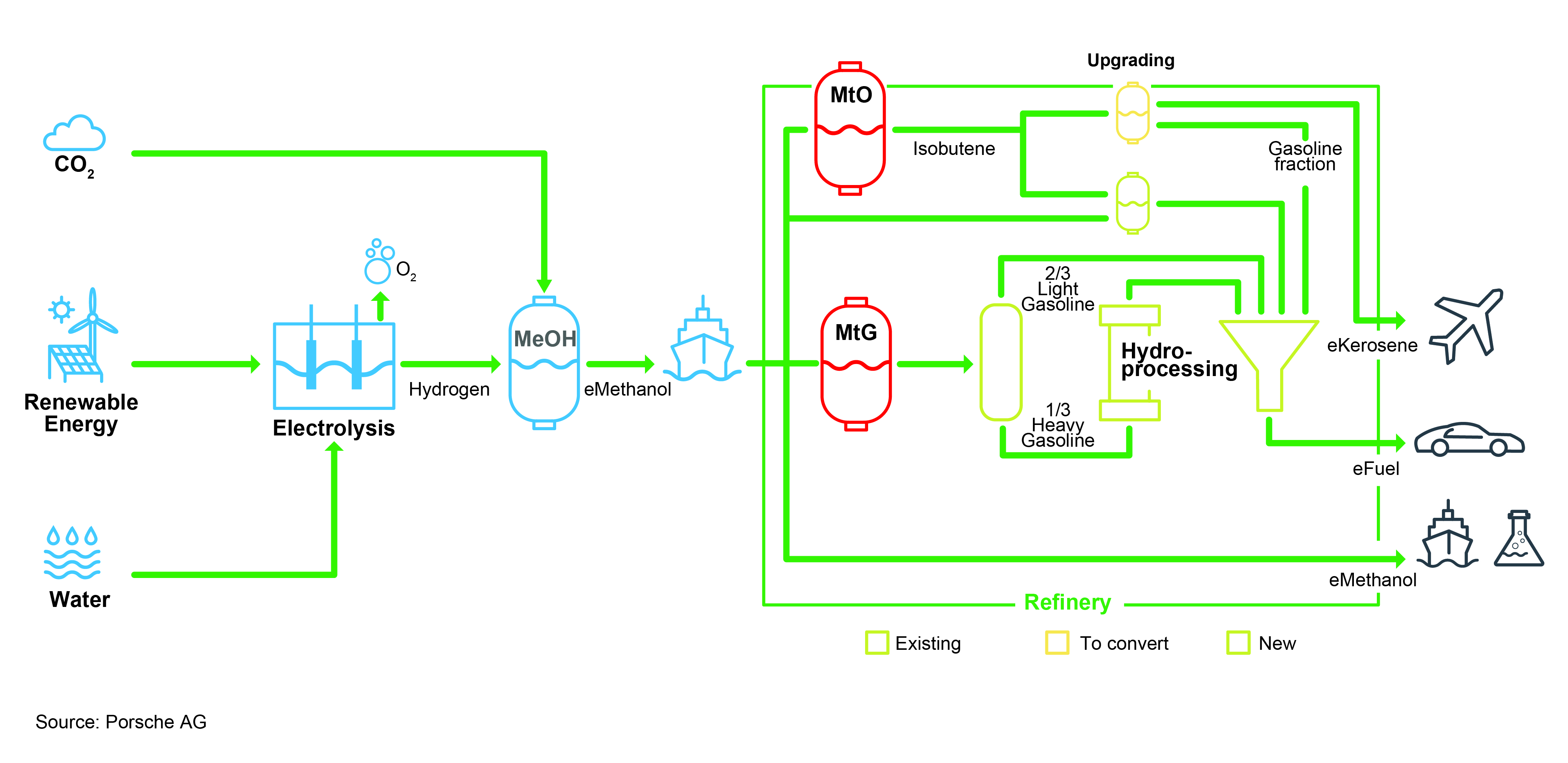

The production of e-fuels requires essentially four steps:

Hydrogen production

Carbon dioxide (CO₂) or nitrogen (N2) capture

Synthesis of the feed gases into ammonia or methanol

Upgrading of the raw product to e-fuels

According to the International Energy Agency report “The Role of e-fuels in Decarbonising Transport”, e-fuels are low-emission fuels when their hydrogen is produced using low-emission electricity and any carbon inputs are obtained in a way that leads to low life-cycle greenhouse gas emissions. However, the water from which hydrogen is derived is a very stable chemical compound, which means electrolysis for hydrogen production requires a great deal of energy. This makes the high availability of green electricity a vital part of this production process.

IEA suggests that, underpinned by a massive expansion of cheaper renewable electricity and anticipated cost reductions of electrolysers, e-fuels could scale up rapidly by 2030 and be a viable pathway to decarbonisation.

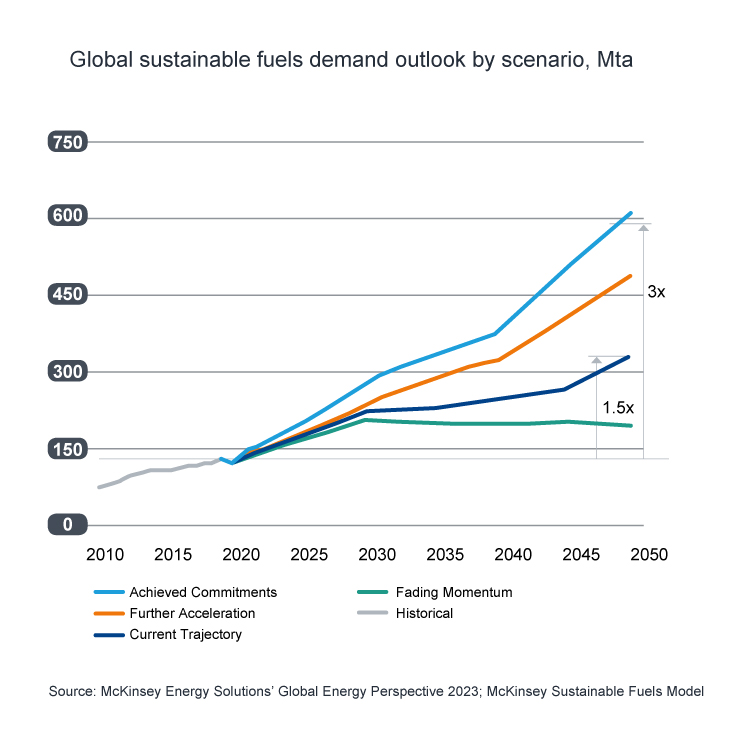

Global management consultancy McKinsey & Company forecasts that demand for sustainable fuels, including bio- and e-fuels, is expected to grow significantly, tripling by 2050 in some scenarios. They expect e-fuels to play an increasingly important role in transportation sectors, including hard-to-abate sectors such as aviation, maritime, and heavy-duty road transport.

The Porsche pilot Haru Oni e-fuels plant in Punta Arenas, southern Chile is the first operating e-fuels facility in the world. The product of an initiative by Porsche and the Chilean company HIF Global, it has been producing synthetic fuels since late 2022. Here the electricity needed to split the hydrogen from water is generated from wind turbines that can operate at maximum capacity for an incredible 270 days a year, allowing the hydrogen to be generated sustainably and affordably. Hardly surprising that in the local dialect Haru Oni means ‘land of winds’.

The oxygen produced is released to the atmosphere, while the hydrogen is combined with CO2 to make methanol. The CO₂ required for this step can be filtered from the air using direct air capture (DAC), a process by which air flows through a ceramic filter. Once all of the spaces are filled with CO₂, the filter is closed, vacuumed, and heated to release the CO₂, which can then be vacuumed into a tank.

The methanol generated through this process can be stored or transported and could be used in the growing number of methanol-powered ships. However, its use in existing passenger cars requires further processing.

At Haru Oni the final methanol-to-gasoline (MtG) process, which is being pioneered by the project, converts the methanol into e-fuel.

“In concrete terms, one litre of e-fuel requires hydrogen from three litres of desalinated seawater and CO₂ from 6,000 cubic metres of air”

Source

This virtually CO2-neutral fuel is blended and refined so that it complies with the current DIN EN 228 fuel standard, allowing it to be used directly in gasoline vehicles or added to fossil fuels for ongoing emissions reduction. The plant is initially focussing on fuel for passenger cars.

e-fuels will enable engines to run long into the future without the need to burn fossil fuels.

Source

Currently, the system is designed for a maximum production capacity of 130,000 litres, with the e-fuel initially being used for the Porsche Mobil 1 Supercup and other lighthouse projects. However, e-fuels also represent a solution for other traffic sectors where electrification is more difficult, such as aviation and marine applications. Making some comparatively minor modifications to the plant would enable the e-methanol to be converted into products such as e-kerosene.

By 2026, it is expected that 55 million litres of fuel will be produced at Haru Oni and, just two years later, 10 times that amount.

Source

This production ramp up means that by 2028, the facility will be producing 550 million litres - equivalent to 1.2% of Germany’s fuel requirements for passenger cars. As Porsche rightly says, a new beginning with high potential.

Sign up to receive monthly updates via email