Commercial vehicles

PC-12 on track for 2027

26 August 2025

14 October 2015

Heavy-duty engine oils help to improve fuel economy performance

As the need to reduce the fuel consumption of heavy-duty diesel vehicles grows, Georgina Hallworth, Infineum Commercial Vehicle Lubricants Team Leader, talks about the challenges of developing robust lubricants that also contribute to fuel economy.

A range of initiatives are being introduced to improvethe fuel economy of trucks

Unlike the passenger car market, where fuel economy performance is mainly being driven by legislation, in the European heavy-duty diesel (HDD) market other issues are in play. While some local incentives do exist, and future CO2 emissions legislation is on the horizon, it is currently the need to cut the cost of vehicle ownership that is driving change. Even in North America, where GHG emissions legislation is already in place, many OEMs feel the added competitive pressure of reducing the cost of vehicle ownership.

With fuel representing around 30% of total truck operation costs it is hardly surprising that fleet owners are looking for trucks with enhanced fuel economy. And, because even small reductions in fuel consumption can significantly improve the bottom line of large fleet operators, the research into fuel efficiency is wide ranging.

OEMs are introducing an array of initiatives to capture fuel economy gains, from the obvious more aerodynamic designs and weight reductions to more advanced engine downspeeding, powertrain control software and waste heat recovery systems. But, fuel economy improvements are not the sole preserve of OEMs; lubricant design can also enhance fuel economy performance via viscosity control and friction reduction.

Lowering lubricant high temperature high shear (HTHS) viscosity reduces the overall friction in the engine, and is a key enabler to deliver HDD fuel efficiency gains. However, reducing lubricant viscosity creates a whole new set of challenges including:

It is essential when designing low viscosity HDD lubricants to ensure that these challenges are carefully balanced so they do not outweigh the potential fuel economy benefits.

HDD lubricants have several key constituents – the base oil, the viscosity modifier (VM), pour point depressant (PPD) and the additive package. Each of these aspects must be carefully considered to ensure that the final formulations deliver sufficient protection and the required level of fuel economy improvement.

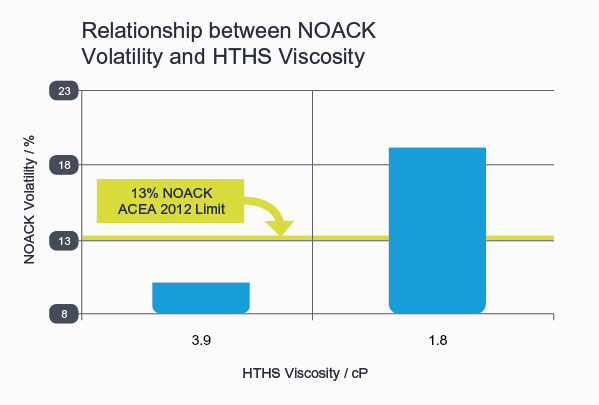

The base stock, which accounts for 60-80% of the formulation, has a significant impact on both viscosity and volatility.

Lighter base stocks contain shorter more volatile hydrocarbons, and this means the lighter ends of the hydrocarbons in the lubricant can evaporate more readily. This pushes the viscosity of the lubricant up and, as a result, any fuel economy improvement gained from the low viscosity of the oil may be lost due to an increase in friction. The use of higher quality base stocks can minimise this effect, however they may not always make a difference in very low viscosity lubricants.

Decreasing HTHS delivers fuel economy gains but can lead to higher volatility, which can potentially impact oil consumption and viscometrics

To produce effective low viscosity lubricants, base stocks with lower viscosity, higher viscosity index (VI) and lower volatility are needed. Clearly the fine balance between viscosity and volatility is an important consideration that must be addressed in the design of innovative additive technologies, which must offer optimum wear protection and fuel economy performance.

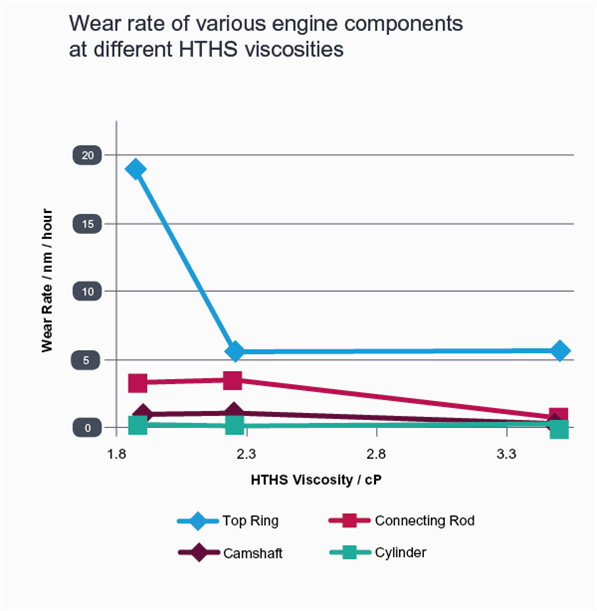

From what has already been noted in this article, you might think that the lower the viscosity of the lubricant the better its fuel economy performance. But unfortunately, as with most complex systems, things are rarely that straightforward. As viscosities get lower, it is possible to reach a point where the lubricant film becomes so thin that the metal parts touch one another and the contact enters a boundary lubrication regime. This increases friction between the parts, which can then outweigh the benefits gained from reduced hydrodynamic friction. It is therefore essential to strike the right balance between HTHS and fuel economy – a relationship that is dependant on the engine hardware and driving conditions.

At the same time, because wear rates are not always predictable and can be hardware specific, Infineum continuously invests in research to better understand the response of different hardware and coatings to viscosity changes. In our experience, higher wear rates can be observed in specific engine components as HTHS viscosity is reduced.

Specific engine components observe higher wear rates as HTHS viscosity is reduced

Bearing wear is one area to which Infineum has given special attention. OEMs are introducing stop-start engines to help deliver fuel economy credits, and this, combined with lower viscosity lubricants, means the bearings can experience significantly more strain over their lifetime in the engine.

It is increasingly essential to work closely with OEMs to understand how materials and hardware strategies will evolve as they look to push the fuel economy envelope to its limits.

Another critical area is the retention of viscosity over the life of the oil. To improve profitability, fleet operators need to keep their vehicles reliably on the roads and out of the maintenance shops for as long as possible. This means that lubricants must continue to deliver their performance attributes over the entire drain interval. To do this, high quality additives, VMs and base stocks can be used to control oxidation, volatility and soot induced viscosity growth allowing viscosity to be maintained over the oil’s lifetime - thus retaining the fuel consumption credit over oil drain interval.

By understanding the complex relationship between the oil, hardware, drive cycle and fuel economy Infineum can minimise the compromises that need to be made at lower viscosities so that the additive solutions deliver fuel economy and hardware protection.

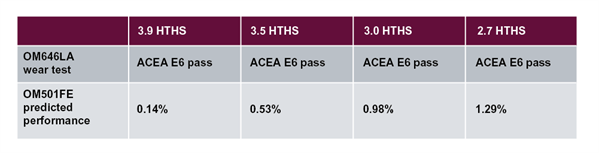

Infineum has used this knowledge to design additive technology that delivers fuel economy improvements whilst maintaining performance across a range of viscosities.

The latest study has demonstrated the robust performance of a 2.6 HTHS oil in API CJ-4 and ACEA E9 specifications and in multiple field trials with a variety of OEMs.

Clearly, reducing the viscosity of HDD lubricants is a significant route to achieve fuel economy gains. However, this approach brings volatility and wear challenges that need to be understood and balanced, to ensure they are outweighed by the fuel economy benefits. Close cooperation with OEMs is increasingly essential to ensure lubricants continue to deliver the desired performance and that viscosity levels are retained over their lifetime in the crankcase – despite the continual hardware evolution.

In our view, it makes very little sense to trade engine durability for fuel economy gains and it is essential that we engineer a workable balance between these two factors.

At Infineum, our research has demonstrated that the careful balance of base stock, VM, PPD and additive package can deliver robust low viscosity lubricants capable of delivering fuel economy over the drain interval without compromising engine durability.

Sign up to receive monthly updates via email