Marine engines

OEMs outline challenges ahead

08 December 2025

Please note this article was published in August 2015 and the facts and opinions expressed may no longer be valid.

12 August 2015

Marine Environment Protection Committee moves forward with environmental initiatives

The International Maritime Organization’s Committee responsible for reducing marine pollution continues its drive to develop regulations and recommendations to reduce emissions from ships.

The IMO says shipping transports about 90% of global trade but, when its productive value is taken into account, it is statistically the least environmentally damaging mode of transport. Even so, the IMO’s Environment Protection Committee (MEPC) is tasked with the introduction of measures to prevent and control the pollution caused by ships.

At MEPC’s 68th meeting a number of decisions and actions were taken that will continue to impact ship hardware and operation, the lubricants they use and the fuels they burn; with the long-term aim of reducing the environmental impact of the international shipping fleet.

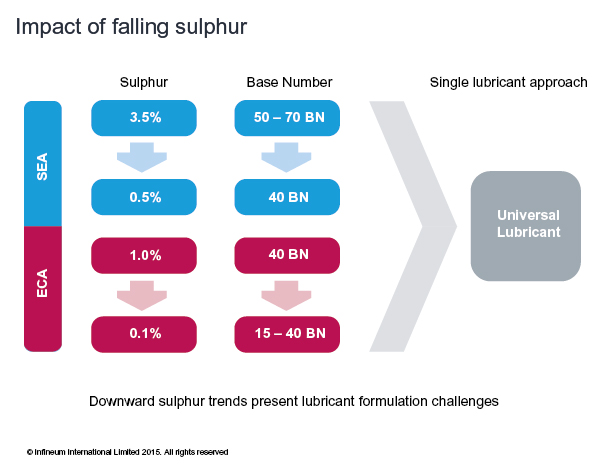

Sulphur reduction has been high on the agenda for some time and, since 2008, sulphur limits in open waters have fallen from 4.5 to 3.5% m/m - a drop that did not preclude the use of heavy fuel oils.

On January 1 2020 the sulphur level at sea is set to fall again from 3.5% to 0.50% m/m. However, there are some concerns about the availability of low sulphur fuels that will be required to help meet this target.

MEPC has agreed the terms of reference for a review of the availability of fuel oils that meet the new sulphur target and the IMO Secretariat has been asked to initiate it by September 1 2015. The final report should be submitted to MEPC 70 in autumn 2016, and will help inform the decisions on MARPOL Annex VI that need to be taken.

A Steering Committee consisting of 13 Member States, one intergovernmental organisation and six international non-governmental organisations has been established to oversee the review.

Depending on the outcome of the fuel availability review, the requirement to cut sulphur to 0.50% m/m outside ECAs could be deferred to January 1 2025.

In emission ECA sulphur was cut by a factor of ten in January 2015 to 0.1% and there are no plans on the table to reduce this further. This huge change means ships entering these waters that burn HFO at sea must now either install scrubbing equipment or switch to low sulphur fuel or liquid natural gas.

The dual and single fuel approaches being adopted to meet these new limits present a number of challenges including cost, availability, reliability and handling.

The new sulphur limits mean lubricants’ base number need to match the fuel type. High BN is needed for use with high sulphur fuels to neutralise the acids that are produced, while in low sulphur fuels OEMs are looking for lubricants with 40 BN or less. While ship owners would value a single universal lubricant, which could provide protection whatever the fuel, as sulphur levels fall this will be increasingly difficult to achieve.

However, the wider mix of fuels being used to meet the sulphur limits impact lubricant formulation beyond BN.

In lubricants for use in high sulphur fuels it is important to balance BN and ash levels to neutralise combustion acids and maintain the cleanliness of the piston assembly. Engines running on low sulphur fuels need lubricants with lower total BN, improved wear control and better combustion performance. Where dual or multi-fuel engines are used, lubricants need to provide advanced corrosion and wear protection.

In our experience, the wide variety of fuel options means OEMs will typically recommend engine lubricants that are suitable for the most severe fuel in use.

On January 1 2016 the IMO will cut NOx emissions in ECAs from 14.4 to 3.4 g/kWh. To achieve these levels, hardware solutions like selective catalytic reduction and exhaust gas recirculation will be needed. And, although they have both been used successfully in other transport applications, their introduction to ships may not be straightforward. The key issue with EGR is that the recycled exhaust needs scrubbing to remove soot. This is proving difficult to do, which means OEMs are tending to adopt SCR.

The key drawback for SCR, apart from the additional urea equipment and infrastructure required, is the potential fouling due to ash build up. Although this can be cleaned, lubricants with lower sulphated ash levels will be required.

It will be important to learn from the experiences of using EGR and SCR technologies in other transport sectors if technical issues are to be avoided.

The IMO 2014 greenhouse gas study, reported that from 2007 to 2012 on average shipping accounted for approximately 3.1% of annual global CO2 emissions. With an average of between 247 million and 325 million tonnes of fuel consumed annually, the study found that fuel consumption is dominated by three ship types: oil tankers, containerships and bulk carriers and that, consistently for all ship types, the main engines are the dominant fuel consumers.

Looking ahead, IMO expects maritime CO2 emissions to increase significantly in the coming decades.

Depending on future economic and energy developments, their ‘business as usual’ scenarios project an increase by 50% to 250% in the period to 2050. This has prompted further action on efficiency and emissions to help mitigate the emissions growth.

At the recent meeting, MEPC continued to develop guidelines to assist in the implementation of the mandatory energy efficiency regulations for international shipping. The amendments to update the 2014 Guidelines on survey and certification of the Energy Efficiency Design Index (EEDI) have been adopted their application is endorsed from September 1 2015, although earlier application is encouraged.

The Committee considered a progress report from the correspondence group established to review the status of technological developments relevant to implementing phase 2 of the EEDI regulations, as required under MARPOL Annex VI, and re-established the correspondence group to further the work and submit an interim report to MEPC 69 in March 2016.

The MEPC data collection system analyses the energy efficiency of ships and work was done to clarify the approach. Ships of 5,000 GT and above will collect data, which includes ship identification number, technical characteristics, total annual fuel consumption by fuel type and in metric tons and transport work and/or proxy data, which is yet to be defined. The methodology for collecting the data would be outlined in the ship specific Ship Energy Efficiency Management Plan (SEEMP).

Data will be aggregated into an annual figure and reported by the ship owner/operator to the flag State, which would submit the data to IMO for inclusion in a database. Access to the data will be restricted to Member States and it will not be possible to identify a specific ship.

MEPC agreed to recommend to the IMO Council that an intercessional working group should further consider transport work and/or proxies for inclusion in the data collection system, assess confidentiality and consider the development of guidelines identified in the text. A report will be submitted to MEPC 69.

A submission from the Marshall Islands calling for a quantifiable reduction target for greenhouse gas emissions from international shipping was considered. MEPC recognised that, despite the measures already taken, more could be done and agreed the proposal needs further consideration. However, the Committee decided that the priority should be to continue its current work, in particular to focus on further reduction of emissions from ships through the finalisation of a data collection system.

At the 68th meeting MEPC also adopted and approved a number of amendments and revisions to existing guidance and requirements related to air pollution measures.

Sign up to receive monthly updates via email