Driveline

Rising demand for DCT fluids

09 December 2025

28 May 2024

Decarbonisation drives demand for dedicated e-fluids designed to deliver durability and energy efficiency in electrified vehicles

The need to meet decarbonisation targets and sustainability ambitions is driving the electrification of passenger car powertrains. Whether that is full-electrification or hybridisation, OEMs are looking for driveline fluids that meet the specific performance needs of electrified drivetrains and improve energy efficiency. Following his recent presentation at the Society of Tribologists and Lubricant Engineers Annual Meeting, Infineum Senior Technologist, Hitesh Thaker, talks to Insight about the careful formulation optimisation that is needed to develop e-fluids that can meet all of these requirements.

It is estimated that the transportation sector accounts for some 16% of todays’ global greenhouse gas (GHG) emissions, with over 70% of these transport related emissions coming from road vehicles. To meet increasingly stringent GHG regulations, OEMs the world over are looking for ways to decarbonise their vehicle line-ups by improving their efficiency.

Currently, most passenger car OEMs see full battery electric vehicles (BEV) as the future net zero option, although there are still challenges to their wider adoption in some regions. Many OEMs are increasing their hybrid offerings as an interim option to significantly cut overall emissions while the barriers to full BEV adoption are addressed and other zero-carbon technologies are further commercialised.

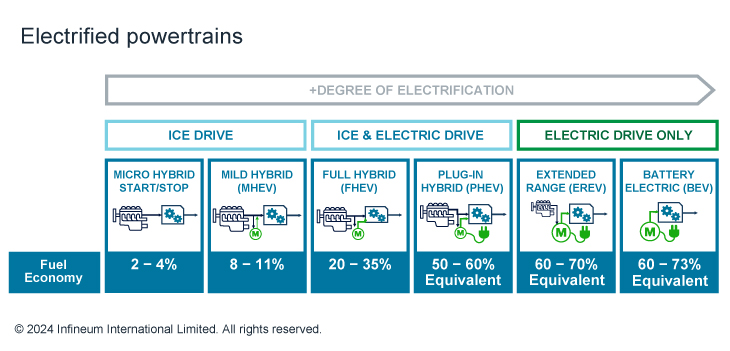

Electrification is one option on the road to net zero emissions but, it is important to clearly understand the definitions of electrified vs fully electric vehicles

Electrified vehicles come in a wide range of formats, each delivering different degrees of efficiency depending on how much the battery and motor are used for vehicle propulsion.

Despite the fact that electrified vehicles are already highly efficient, OEMs are looking for ways to decarbonise and get more miles out of a single charge. Weight reduction and increased power density are two of the options currently being explored and we are also seeing a growing interest in combining the e-motor, gearbox and power electronics into one housing. However, this latter approach does lead to increased complexity in terms of design and higher working temperatures, especially in compact spaces, making thermal management even more critical. Oil cooling of integrated e-motor designs is an efficient option for thermal management, and this has led to the development of dedicated e-fluids.

The increasing complexity of electrified vehicles means there is a growing need for more advanced e-specific fluids.

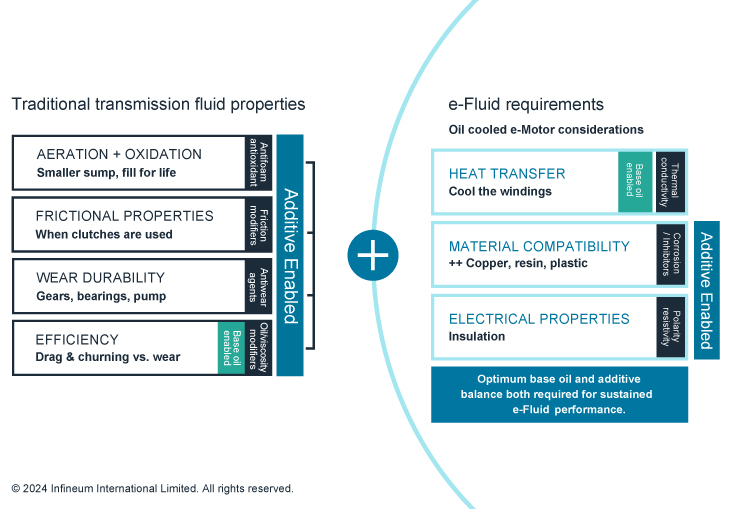

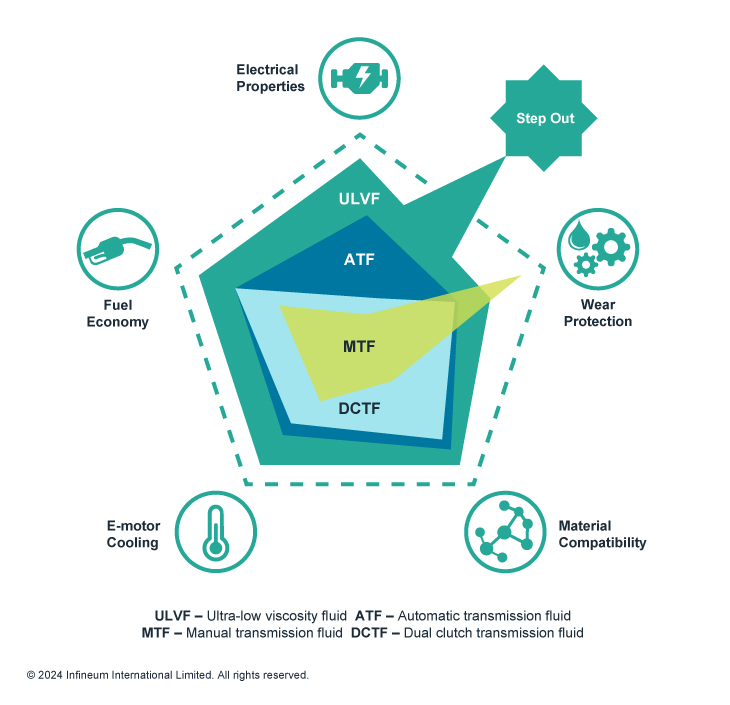

Advanced e-fluids need to meet a broad range of requirements. First they must provide the gear and bearing protection delivered by traditional transmissions fluids at lower viscosity for efficiency gains. In addition, e-fluids must offer new e-motor cooling, electrical properties and material compatibility driven by the higher temperatures, higher voltages and new materials with which they come into contact in hybrids and BEVs. It is vital that specialised e-fluids also deliver the range, durability and sustainability benefits OEMs are looking for without sacrificing wear protection.

Meeting all of these requirements is a careful balance - particularly in today’s even lower viscosity environment.

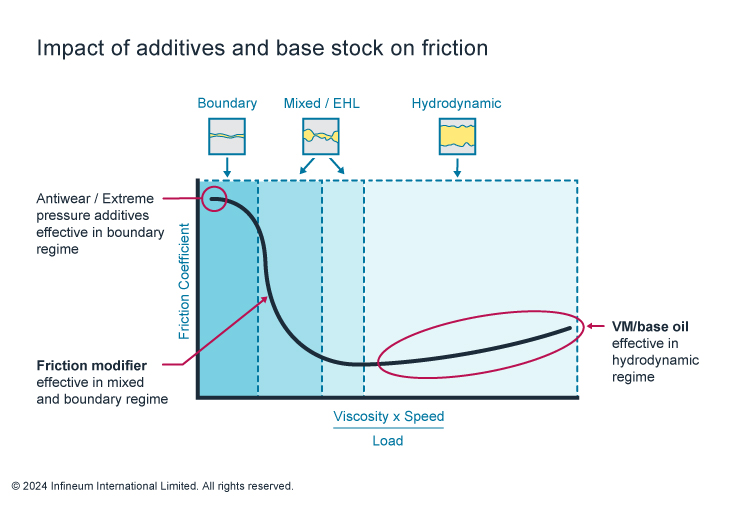

In our recent research programme, we have assessed the impact of different additive technologies and base stocks on energy efficiency in an electric drive unit (EDU). It is known that additives play an important role in reducing friction in the mixed and boundary lubrication regimes, while base stocks and viscosity modifiers (VM) have a more significant impact on friction in the elastohydrodynamic lubrication (EHL) regime (as shown in the Stribeck curve below).

The testing work explored a variety of formulations with different base stocks, viscosities and additives under both steady state and the Worldwide Harmonised Light Vehicle Test Procedure (WTLP) testing. All test formulations were run against a commercial fluid.

The practical implications of our findings in the WTLP testing are evident. Lowering the viscosity and using higher quality base stocks resulted in energy efficiency improvements over the commercial fluid. However, the addition of a boundary friction additive did not further improve the results under these WLTP conditions. Similar observations were made in steady state testing at 30oC – with lower viscosity fluids more efficient at higher speeds.

Similarly, in steady state testing at 70oC, lower viscosity fluids were more efficient at higher speeds, but showed a debit at lower speeds. On the other hand, the boundary friction additive improved efficiency at lower speeds.

These results help to identify the most efficient additive, viscosity modifier and base stock combination. This knowledge is crucial to improve the efficiency of electric vehicles under various conditions and directly impacts what we do as we work to design more efficient fluids.

As the number of electrified vehicles continues to rise and their performance requirements evolve, the need for dedicated e-fluids is growing.

The new generation of e-fluids need to provide gear and bearing durability while also delivering enhanced fuel economy performance for hybrids and higher pure electric range for BEVs . For oil cooled e-motors, they must also deliver motor cooling, protect the motor and electronics by increasing volume resistivity, and deliver protection to exposed copper, coatings, plastics, and sealants.

By optimising a careful balance of advanced additive technologies, including antiwear and extreme pressure chemistries, Infineum has developed additive packages for ultra-low viscosity e-driveline fluids. These specialised products have been designed to meet all the requirements of hybrid and full electric vehicles while also providing the increased efficiency OEMs are looking for.

Contact your local representative to see the full results of this e-fluid efficiency study.

Sign up to receive monthly updates via email