Fuels

Reported sludging incidents rise

04 November 2025

Please note this article was published in September 2012 and the facts and opinions expressed may no longer be valid.

01 September 2012

Japanese winter field trials confirm fuel additive performance

Braving the freezing temperatures and biting winds, the Infineum Fuels Team has completed a series of rigorous field trials in Japan. Working closely with OEMs and oil companies, the trials are a good way to validate fuel additive performance in real world conditions, rather than solely relying on laboratory tests.

The Japanese winter field trials have run almost every year for the past 30 years. They are carried out in Asahikawa-city, Hokkaido, on Japan’s north island, where the Fuels Team starts the tests before dawn in temperatures that on some days drop below -20°C.

Oil companies and OEMs from Japan, Korea, Thailand and China join Infineum so that they can gain a better understanding of the behaviour of wax in diesel fuels and its effect on vehicle operability and to learn about the impact of cold flow improver additives on fuel performance in these severe conditions.

This year, throughout January and February, 12 fuels from five companies were tested in Isuzu Elf trucks.

Around the world, stringent emission legislation is driving change in both engine design and fuel quality.

In Japan oil companies are producing high quality low-sulphur diesel fuels with a range of distillation characteristics and compositions and, at the same time, OEMs are continuing to evolve the design of engine hardware and aftertreatment devices.

Any changes to the characteristics of fuels mean vehicle performance testing is vital to ensure end user satisfaction. The Asahikawa field trials provide the perfect opportunity to evaluate the low temperature performance of new fuels and additive technologies.

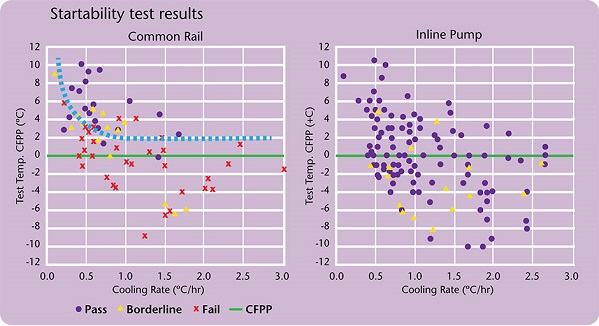

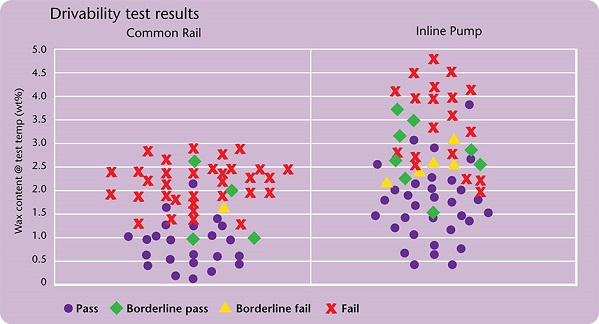

The field trials examine two vehicle operability parameters: startability, to assess fuel supply pump filter blocking, and drivability, to examine main filter plugging.

Wax crystals start to form in the fuel when the temperature drops below the cloud point and these tests determine the effects of wax precipitation on vehicle operability.

The startability test assesses if the engine will continue running following the first ignition.

Failure to start is attributed to the blocking of the fuel supply pump filter with wax crystals. If the filter becomes clogged with wax, fuel will not reach the fuel injectors and the engine will stop. In cases when the whole filter is covered with large wax crystals, the engine may not even start.

In modern common rail injection systems fuel is pressurised by the supply pump, which in some cases is fitted with a filter to protect its components. In older inline pump systems, the filter size of the prefilter was 350 micron, however today’s pumps have much finer filters – normally 150 micron.

This reduction in mesh size makes them even more susceptible to filter blocking.

The drivability test determines if the vehicle will continue to run at 50 km/hour throughout the duration of the test.

If wax precipitates in the fuel it blocks the main filter and disrupts the amount of fuel flowing to the common rail fuel injectors, which means the vehicle slows down despite the best efforts of the driver.

In severe conditions wax accumulates gradually on the 5 micron filter until a thick coating builds up over its entire surface, at which point fuel flow stops. The field trials indicate the impact of wax on low temperature vehicle performance.

Most of the fuels show good drivability results although some gaps in CFPP and minimum pass and borderline temperatures are apparent.

It appears that the amount of wax present in the fuel is the critical factor affecting performance in this test – the higher the wax content the poorer the performance.

These data allow fuel quality to be improved by using cold flow additives to control the size of the wax crystals.

The tests demonstrate that the engine starts smoothly when middle distillate flow improver (MDFI) additives are used to modify the wax crystals from thin and flat rhombic plates to thin needle shapes. Additised fuels flow through the supply pump filter without any disruption.

Fuels containing Infineum wax anti settling additives (WASA) have smaller wax crystals than those without additive.

WASA supports the dispersancy of wax crystals in the fuel at temperatures below the cloud point and modifies wax crystals, making them smaller and ensuring that the engine keeps running steadily for longer periods.

The data generated in these trials confirms that technology from Infineum performs very well in severe conditions.

By working proactively with these industry stakeholders Infineum is well placed to help them avoid future field issues in cold conditions and can advise oil companies on the most effective ways to improve their fuels to meet cold temperature operability targets in the latest vehicles.

The Asahikawa field trial is a good opportunity for oil, additive and OEM companies to better understand the performance of their latest products in real life conditions. It offers a unique opportunity for technical collaboration in the design of the most reliable middle distillate fuels for end users.

Sign up to receive monthly updates via email