Passenger cars

ASEAN a market in transition

09 December 2025

09 July 2024

Lubricants designed to meet the demands of a growing hybrid market excel in trials

As the world works to transition to a net zero emissions future, the number of electrified cars in use is continuing to grow. And, with some barriers to battery electric vehicles still to be overcome, hybrids are an increasingly popular choice, which means they will make up a significant part of the vehicle parc for many years to come. This Insight article explores the lubrication challenges hybrids present and how the Infineum Hybrid Test Protocol can be used to test lubricants against them. It also reveals the results of a recent field trial, designed to assess the performance of bespoke hybrid lubricants in tough real-world driving conditions.

Full electrification is seen as the future for net zero passenger car powertrains. However, internal combustion engine (ICE) containing hybrid vehicles are proving to be a very popular lower carbon option in the transition phase, as the remaining barriers to battery electric vehicle (BEV) adoption are overcome.

Read our article on the growth potential of the hybrid vehicle market here.

In essence, what we see is that, even in a market where the share of BEV powertrains grows quickly, hybrid electric vehicles (HEV, which includes mild, full and plug-in hybrids) will continue to be a large part of the passenger car production mix for many years to come.

Using production forecasts, we estimate that by 2030 there could be some 266 million HEV on the road.

In our view, this growing volume represents an opportunity for the development of tailored engine oils that meet the specific requirements of hybrid platforms.

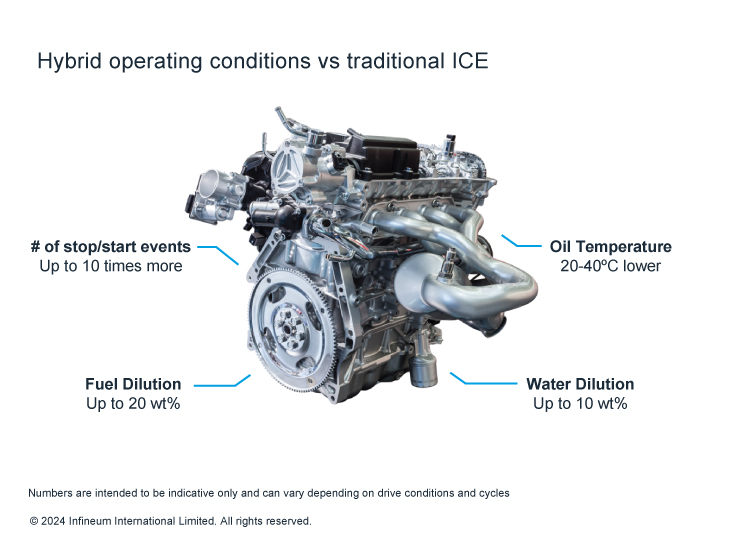

Hybrid engines operate differently compared to traditional ICEs. Most notably, hybrid engines undergo frequent yet intermittent use of the ICE, where high-power start/stop events generate higher stress on bearings. At the same time, cold starts and lower ICE operating temperatures can lead to fuel and water entrainment. Fundamental understanding of these phenomena enables the development of improved lubricants that can deliver additional protection.

Conventional passenger car engine oils can provide acceptable performance to solve most of these challenges. However, specifically formulated oils can provide extra protection to tackle these challenges even under the most severe hybrid duty cycles.

The increasing market penetration of hybrids presents finished oil marketers with an opportunity to differentiate their product offering and capture niche incremental value. However, the case for differentiated hybrid specific products can be difficult to build, leaving oil marketers with a number of challenges to overcome. The key one being the current lack of e-ICE lubricant specifications. This means only limited data is available to demonstrate the performance benefits and capabilities of high quality hybrid fluids to OEMs and end users.

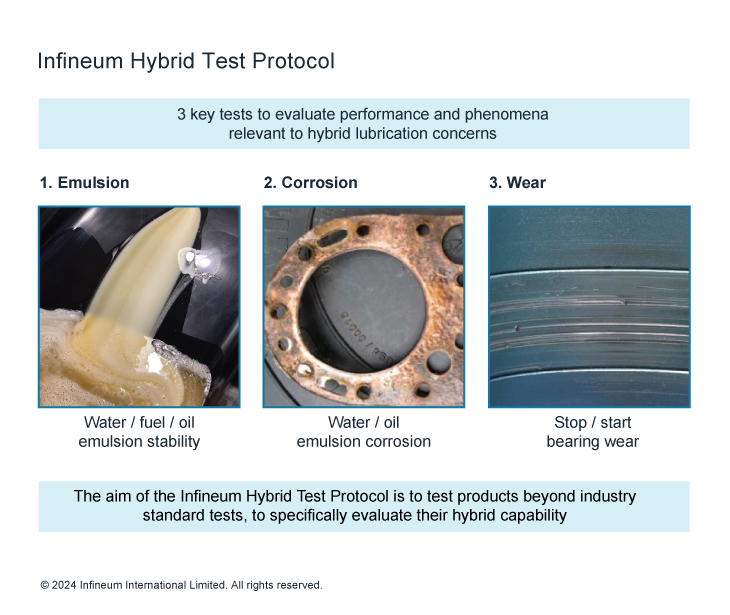

The lack of hybrid-dedicated tests, and the limited number of tests in the industry incorporating hybrid challenges, led Infineum to develop a Hybrid Test Protocol.

This Infineum test protocol is being used to test our lubricants against key hybrid-related challenges and to evaluate their hybrid capability. In addition, a robust field trial has been used to stress-test and demonstrate the performance of lubricants in the most severe conditions hybrid duty cycles can present.

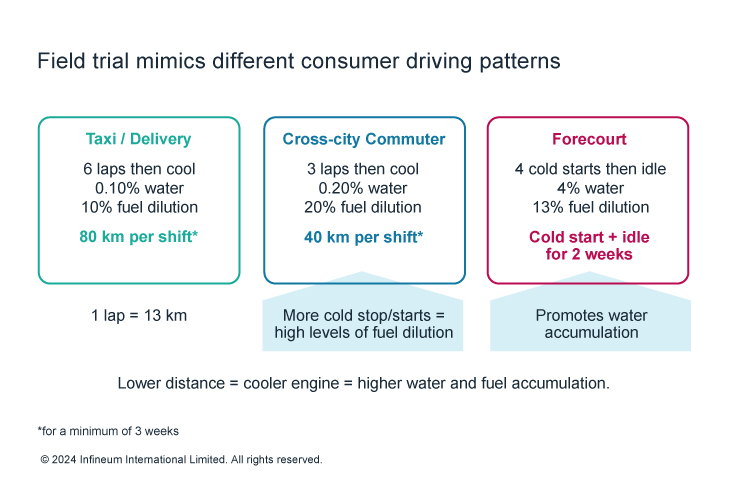

Infineum developed a very severe field trial to evaluate a number of test oils under various test conditions:

Urban cycle with a high frequency of stop-start events.

Cold climate to increase the incidence of high-power high-speed cold start.

Varying cycle repetitions to mirror different consumer use cases.

Electrified and ICE-only versions of the same vehicle model were used in the trial to simulate three different energy configurations (ICE, mild HEV and plug-in hybrid electric vehicle (PHEV)) using the same ICE hardware. The mileage was varied to mimic different users from taxi drivers to cross city commuters and, the most extreme, forecourt demonstrations.

The trial was run using 16 vehicles in Heihe, a city situated in the far north of China, where air temperatures can plummet to -40oC in the winter months. The duration, cold temperatures and test cycles were chosen to stress the lubricants in conditions promoting fuel dilution, water entrainment and cold corrosion. After 15,000 km the inspection summary gave insights into the performance of the different oils.

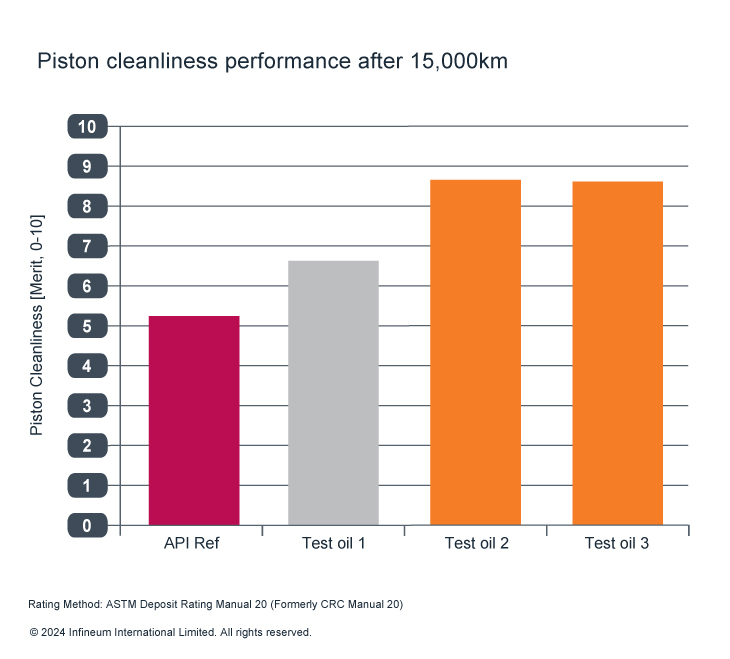

When compared to the ILSAC GF-6 reference oil, the bespoke hybrid formulations delivered improved piston cleanliness performance. The rating results indicated that some of the test oils demonstrated exceptional performance in deposit control and sludge dispersancy throughout the field trial.

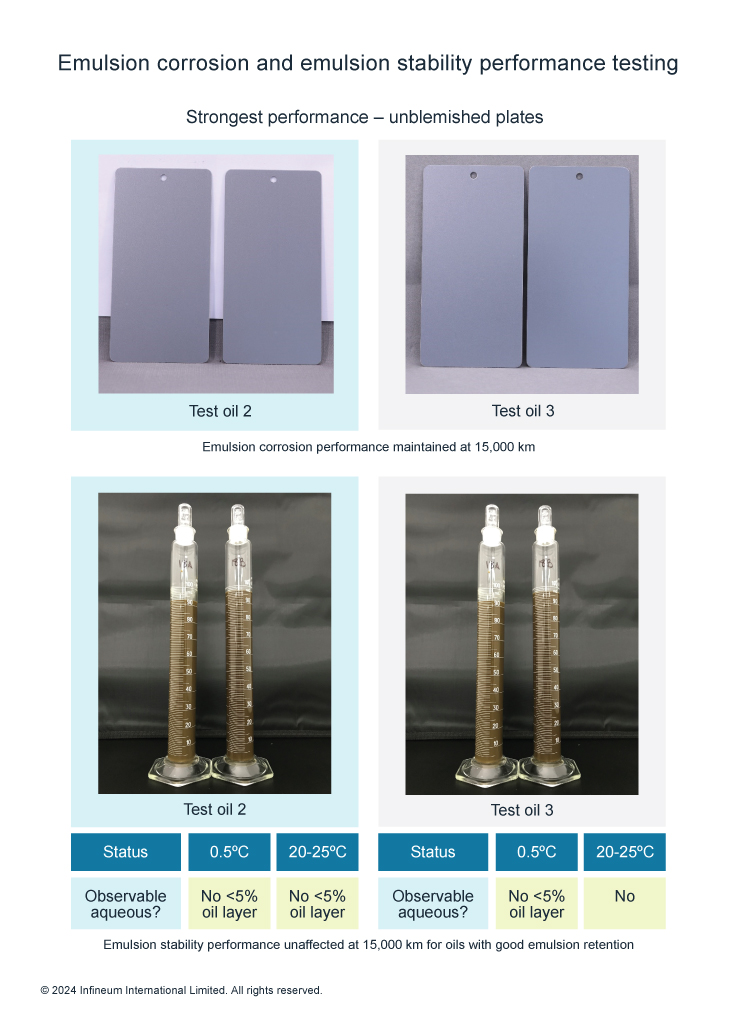

In addition, test oils 2 and 3 delivered exceptional emulsion stability and emulsion corrosion performance, obtaining the maximum score in the corresponding bench tests of the Infineum Hybrid Test Protocol even when tested after aging over 15,000 km.

Across the globe, OEMs are recognising that hybrid duty cycles create specific issues. More tests targeting hybrid challenges should find their way into industry and OEM specifications, and the introduction of new specifications designed to meet the specific needs of hybrid vehicles is a future possibility. API made some announcements in that respect at the F&L Asia Week Conference.

The hybrid vehicle parc is continuing to grow, presenting an opportunity for differentiated engine oils to meet the specific requirements of OEMs and end users.

Bespoke hybrid solutions can be developed to deliver additional performance in areas where the hybrid drive cycle puts the engine under additional stress and to deliver the driver experience, comfort and performance end users expect.

To support the growing number of hybrid vehicles, Infineum has extensively researched the impact of hybrid operating conditions on lubricant performance and identified performance features that signify robust in-field hybrid capability. Our field testing, designed to put hybrid applications through severe conditions, enabled us to further our understanding of the associated challenges, and to demonstrate the strong performance of some of our products even under these extreme conditions. We are ready with field-proven hybrid fluids to cover a broad spectrum of OEM requirements, now and into the future.

Sign up to receive monthly updates via email