Fuels

Reported sludging incidents rise

04 November 2025

13 January 2016

Additives address diesel fuel filterability performance concerns

Field issues in Europe and North America, where on-specification diesel fuels above the cloud point blocked fuel filters, have spurred fuel quality improvements to protect today’s vehicles.

Enhanced fuel injection equipment (FIE) is one technology helping OEMs to meet increasingly stringent engine efficiency and vehicle emissions targets. To ensure they deliver optimal combustion and reduced emissions, injector manufacturers are increasing injection pressures, making nozzle holes even smaller and introducing multiple injections. These changes result in higher temperatures, increased contact pressures and tighter tolerances.

Modern injectors, where the clearance of moving parts is a couple of microns, force fuel through openings the size of a human hair at around 2,000 km/hr. This means reliable fuel quality is essential to maintain durability and to ensure emissions compliance over their lifetime in the engine.

Contaminants in the fuel, which could result in deposit formation and FIE damage, are removed by filtering the fuel in the distribution system and in the vehicle before it enters the fuel injection system. To ensure acceptable performance these filters have specified periods of service. In normal operation, although fuel dispenser or engine filters may collect deposits, they should continue to deliver good performance over their designed lifetime.

In certain circumstances, the contaminants collected can block the filter medium, which drastically reduces the longevity of the filter, and may result in fuel starvation and engine operating difficulties.

It is well known that at low temperatures, below the cloud point of the diesel fuel, wax precipitates from the fuel and can cause filter blocking. This scenario is routinely handled by the use of cold flow additives. Standard industry tests and quality specifications are used to ensure that diesel fuel sold at the pump is fit for purpose. However, filterability issues have recently been observed at terminals, retailers and in vehicles, both in the US and in parts of Europe.

What is of real concern is that recent incidents occurred above the cloud point, and in on-specification fuels.

Many factors can contribute to poor filterability in these conditions, including: microbes, soaps, waxes, poorly blended cold flow additives, polyethylene, water and by-products of oxidation. In addition, filter blocking is also influenced by fuel type, supply chain management, housekeeping to control algae and microbes and the climate, making the issue challenging to study, hard to measure and difficult to rectify.

Some field issues have been associated with the introduction of FAME as a diesel fuel blend component. For example, the role of low solubility impurities (saturated monoglycerides and sterol glucosides) found in these fuels, which precipitate above the cloud point, have been identified as one key cause.

Other factors associated with the use of FAME could also contribute, though are not fully understood. The surface active nature of FAME molecules, for example, means they can react with cations in the bottom of fuel tanks, quickly leading to the formation of soaps, which can consume any corrosion inhibitor present. In addition, long chain waxes, such as behenyl behenate, which can be present in FAME, may cause filtration issues; although these can be treated with conventional cold flow additives.

The water content of biodiesel is one of the most difficult contributing factors to control.

Water has been shown to exacerbate filterability problems, especially in the presence of saturated monoglycerides and sterol glucosides. Water content of biofuels can increase throughout the supply chain and has been shown to have seasonal fluctuations.

Filterability above the cloud point is becoming an increasingly important fuel quality feature. Unfortunately, field problems linked to vehicle fuel filter blocking have occurred over the last two winters in Italy, France, Sweden and, most notably, in the UK.

Although experienced by a small proportion of vehicles, fuel filter blocking causes unacceptable performance with engines failing to start and vehicles ‘limping home’.

The British Standards Institution (BSI) set up a task force to investigate the issues. Representatives from the Downstream Fuel Association, the Petrol Retailers Association, the Society of Motor Manufacturers and Traders (SMMT), the United Kingdom Petroleum Industry Association, the UK Department for Transport (DfT) and Oil Industry Additive Manufacturers were included.

As a result of the efforts of the BSI task force a filter blocking tendency (FBT) limit has been introduced in the UK’s national EN590 specification.

The test is an interim precautionary measure, which aims to mitigate the exposure to consumers whilst the cause is identified.

Infineum worked to understand this issue, both supporting the BSI task force and independently to provide advice to refineries on the best practice for blending cold flow additives into their fuels. In addition to investigating the ways additives could be used to improve filterability issues.

A filterability rig has been developed to simulate the issues and give a better understanding of root causes. Despite the task force's activities, the precise cause of the filterability issues remained unclear. Infineum has continued to investigate the effects of both FAME impurities and the base fuel, both as part of the task force and independently. As part of these efforts, Infineum designed and developed a second filter blocking rig capable of replicating the Industry rig but with enhanced modes of actions to replicate suction and pressure modes.

The filter blocking rig is designed to help improve understanding of the root causes

The filter blocking rig is designed to help improve understanding of the root causes

The rig results showed a clear differentiation between known good and failing fuels

The new rig has been used to assess the impact of different fuels, with a variety of contaminants and with FAME levels up to B30. The results indicated that filterability performance is adversely affected by the amount of saturated monoglycerides in the fuel, although other factors are also likely to play a role.

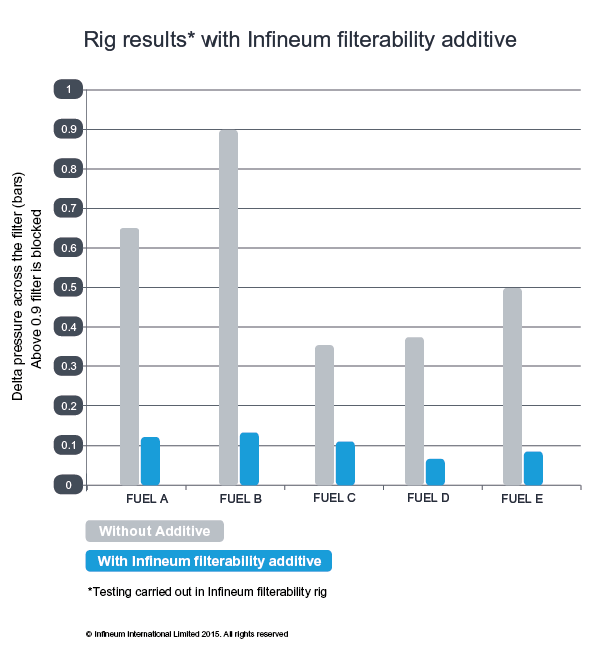

The rig has also been used to assess the effect of additive solutions on the filterability of a broad range of biodiesel feedstocks. Infineum developed a fuel additive that delivered significant filterability improvements, which means its use will help to reduce the risk of future field issues.

Additives deliver significant filterability improvements in a range of commercial biodiesel samples

The filterability additive has also been shown to clean filters that are partially blocked, indicated by increased pressure across the filter. In testing, B25 and B30 fuels were passed through the same filter. The build up of impurities caused the pressure to increase across the filter until the B30 fuel containing the Infineum filterability additive was passed through it. From this point the pressure began to decrease - clearly demonstrating the ability of the additive to clean up the filter.

Additives have the ability to clean up partially blocked filters

The new filterability additive has passed extensive no-harms testing and has been used successfully in the US for three years, with no reported field issues. To test the long-term performance of the additive, samples were stored for between two to eight weeks after which their continued filterability performance was confirmed.

The additive has delivered filterability improvements in a broad range of biodiesel feedstocks, which means refiners can use it to maximise FAME economics and produce fit for purpose fuels that deliver trouble free operation.

Additives deliver filterability improvements in a broad range of biodiesel feedstocks. FBTI below 1.4 indicates the entire sample was filtered within the maximum pressure indicated in the test method

Filterability issues above the cloud point can be problematic for the industry. And, when experienced by the consumer, can result in unwanted publicity, which means solving the issue is a high priority.

While it is not always possible to identify all the causes of filter blocking, there are a number of methods to mitigate the issues.

Infineum, with its experience, understanding and in-house testing facilities, has helped and advised industry stakeholders on how best to reduce the occurrence of filter blocking issues. In addition, the development of novel additive filterability technology means Infineum is able to offer commercialised products that can help to improve the quality and performance of diesel fuels and keep fuels flowing.

Sign up to receive monthly updates via email