Fuels

Driving hydrogen forward

21 January 2025

13 December 2022

Proven combustion improvers can help ships to meet minimum ‘C’ carbon intensity indicator rating

Hard on the heels of the International Maritime Organization IMO 2020 sulphur emissions cuts come the organisation’s initiatives to reduce greenhouse gas emissions from shipping. Part of these measures involve a new carbon intensity indicator (CII) and rating, which is about to take effect. Rob Ashton, Infineum Marine Fuel Additive Market Manager, explains how meeting the minimum ‘C’ rating will not be easy for much of the world’s tanker fleet and discusses some of the actions, including the use of combustion improvers, that shippers can take to help them meet the required targets.

The IMO says it is committed to phasing out greenhouse gas (GHG) emissions from international shipping as soon as possible. A revised GHG strategy, which is expected to be adopted at the 80th session of the Marine Environmental Protection Committee (MEPC) in 2023 sets the ambition to pursue efforts towards net-zero emissions by 2050. As part of the process, mandatory measures such as the Carbon Intensity Indicator (CII) have been introduced as amendments to the International Convention for the Prevention of Pollution from Ships (MARPOL) Annex VI.

CII determines the annual reduction factor needed to ensure continuous improvement of a ship’s operational carbon intensity within a specific rating level.

CII came into force for ships of 5,000 gross tonnage (GT) and above on November 1 2022, and the first annual reporting on fuel consumption will be completed over 2023, which will form a base on which CII can be calculated. This allows the first energy efficiency rating, measured in ‘grams of CO2 emitted per cargo-carrying capacity and nautical mile’, to be made in 2024, when ships will be given a rating from A to E, with an A rating being the best. This straightforward rating system will give a very clear indication of how efficiently a ship transports goods or passengers. Ships rated for three consecutive years as D or for one year as E will have an obligation to adopt a plan of corrective action to improve their energy efficiency performance and bring them back to a C rating.

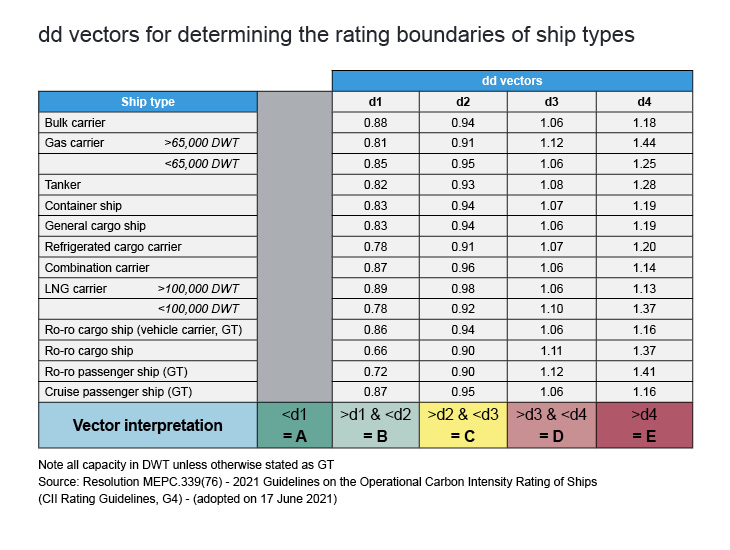

The CII rating is calculated based on a combination of vessel data (fuel consumption, CO2 emissions, deadweight tonnage (DWT) or GT and distance sailed, hours underway) coupled with several calculated variables and correction factors. This yields a numerical value for a vessel’s attained CII vs a calculated required CII. The rating boundaries for a ship can be determined numerically by multiplying the required CII with the dd vectors, which are listed in the table below.

By comparing the attained annual operational CII of a specific ship with the four boundaries, a rating can then be assigned. An example given in the MEPC document shows that given the required CII of a bulk carrier in a specific year as 10 gCO2/(dwt.nmile), then the superior boundary, lower boundary, upper boundary, and inferior boundary are 8.6, 9.4, 10.6 and 11.8 gCO2/(dwt.nmile). If the attained CII is 9 gCO2/(dwt.nmile), the ship would be rated as ‘B’.

The CII contains a reduction factor relative to the 2019 reference line, which starts at 5% in 2023, with 2% added yearly through to 2026. These improvement goals are designed to encourage ship owners to consistently improve operational efficiency across their fleet. And we could expect these thresholds to become increasingly stringent out to 2030. In our view, maintaining the current CII rating alone will be challenging, but vessel operators will need to incorporate a continuous improvement plan to improve their CII in the next few years.

If no corrective action is taken some 70% of tankers are anticipated to be below the minimum C rating by 2030.

Since CII is based directly on fuel consumption, it can be influenced in a number of ways including how a specific ship is operated, its technical efficiency and fuel choice. Several measures can be taken to improve vessel efficiency including reducing drag (which may be via hull coatings and a regular cleaning regime) propellor polishing, optimising power generation with supplementary battery hybridisation and waste heat recovery, operational factor improvement such as slow steaming and route selection. In addition, fuel selection and additive choice can also positively influence the CII rating.

A relatively easy way for a ship operator to positively influence their Ship Energy Efficiency Management Plan (SEEMP) part III & CII rating is to use a proven combustion improver additive. Combustion improvers can help to reduce vessel fuel consumption, lower the CO2 output per nautical mile travelled and lower other key emissions such as NOx, carbon monoxide, total hydrocarbons and smoke. Another benefit of combustion improver use is demonstrable through lower fuel consumption per nautical mile year-by-year and to that effect can become an integral part of how the annual energy efficiency/operational CII can be achieved in the SEEMP. A side benefit of additive use is its powerful fuel stabiliser chemistry, which can help to minimise fuel lost as sludge. This not only enhances the overall fuel consumption of the vessel but also minimises potential sludge disposal costs.

Currently it is estimated that 2% of the global fuel oil pool is lost as sludge, which could instead be a useable fuel if it was managed more effectively.

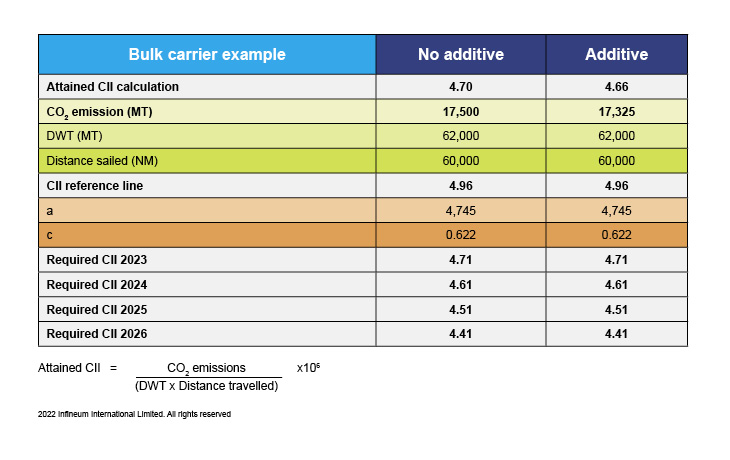

A theoretical example below demonstrates the impact of combustion improvers on CII rating, assuming a conservative 1% fuel consumption saving.

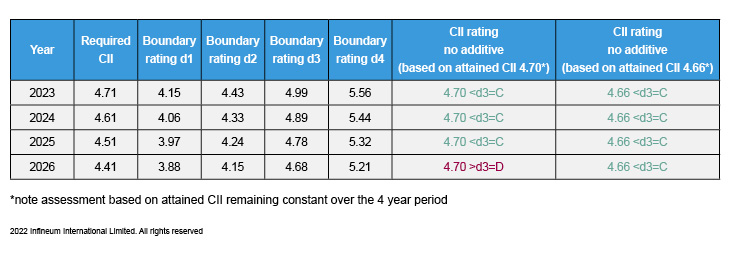

Assuming the attained CII remained constant over the four years, by using the required CII values and calculating the boundary ratings using the dd vectors it is clear, in the table below, that without improvement the vessel using unadditised fuel would fall to a ‘D’ rating by 2026.

Phase one of CII is the assessment of the ship’s baseline energy usage, which will be recorded over 2023. Operators can then assess what measures are necessary to ensure a ‘C’ or above rating will be maintained as the reduction factors are applied and the thresholds become increasingly stringent.

Combustion improver additives can be included as part of an energy saving development plan and be easily introduced via regular bunkering activities.

Performance, in terms of reduced fuel consumption, can be verified against the previously collected baseline data. While sailing conditions, route selection and other factors can heavily influence fuel consumption, in our view, over an extended period of operation the efficiency improvement benefits will be apparent.

Infineum has rigorously evaluated its combustion improver additive technology to accurately determine the potential for statistically significant fuel economy and emissions reduction benefits and to demonstrate its ability to make a positive contribution towards CII.

Using proven additive technology to improve combustion efficiency means more energy is transferred into forward propulsion, less fuel is wasted, NOx and particulate emissions are reduced and hardware stays cleaner for longer. All these attributes translate not only into a positive contribution to CII but also lower running costs and less downtime.

Sign up to receive monthly updates via email