Lubricant trends

Advances in automotive lubricant design

04 March 2025

Please note this article was published in December 2015 and the facts and opinions expressed may no longer be valid.

15 December 2015

Conference explores latest automotive challenges and technology innovations

The second Illuminating Challenges in Automotive Research (ICAR) conference enabled academic and industrial scientists to share their thoughts on the ways advanced scientific techniques can help to solve key automotive challenges.

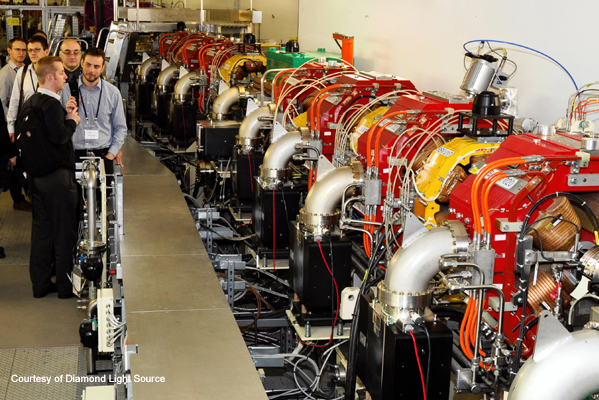

The conference, hosted at Diamond Light Source the UK’s national synchrotron facility, in partnership with Infineum, attracted more than 90 scientists from academia, research institutions and the automotive and petrochemical industries. The event, which was designed to promote wider scientific collaboration, explored the ways fundamental research can be used across a broad spectrum of disciplines to solve some of the world’s most pressing automotive challenges.

Academic and industrial scientists explored how cutting edge science can be used to help overcome the obstacles to greener transportation and energy production.

ICAR opened with an introduction from Diamond CEO, Andrew Harrison, and Infineum EVP Marketing and Technology, Chris Locke. The keynote presentation, delivered by Yann Cramer, General Manager from Shell Lubricants, focused on two potential paths that could help to meet the huge increase in demand for energy demand expected over the next 40 years. He also looked at the potential for technology and societal transformations to impact air quality and fuel efficiency in both the short and long term.

Following a session that looked closely at the way Diamond Light Source works with industry (via an Industrial Liaison team), delegates were given a guided tour of the facilities. This gave them the opportunity to see first-hand the scale of the operation and to discuss the options for conducting advanced scientific explorations on the beamlines.In the first session, under the banner of The Future of Automotive Applications, Penny Atkins, Principal Engineer at Ricardo and Richard Durrant, Global Engineering Manager at Infineum, explored the engine, market and technology trends for passenger car and heavy-duty diesel engines. With tightening legislation and cost reduction driving innovation in engine technology, the two speakers assessed the challenges these market trends will have on OEMs, their suppliers and consumers.

Delegates saw first-hand how the facilities at Diamond are being used to investigate a broad range of

materials under industry relevant conditions

Following a session that looked closely at the way Diamond Light Source works with industry (via an Industrial Liaison team), delegates were given a guided tour of the facilities. This gave them the opportunity to see first-hand the scale of the operation and to discuss the options for conducting advanced scientific explorations on the beamlines.In the first session, under the banner of The Future of Automotive Applications, Penny Atkins, Principal Engineer at Ricardo and Richard Durrant, Global Engineering Manager at Infineum, explored the engine, market and technology trends for passenger car and heavy-duty diesel engines. With tightening legislation and cost reduction driving innovation in engine technology, the two speakers assessed the challenges these market trends will have on OEMs, their suppliers and consumers.

Over the two-day conference, more than 20 speakers presented on a broad range of industry challenges and automotive research areas, describing how the sector might find answers to questions including:

The topics explored included: battery and fuel cell technologies, novel alloys, metal/oil surfaces, the impact of start-stop operation, lubricant structures and other innovative applications of the synchrotron facilities to automotive applications.

The collaboration fostered at Diamond was strongly in evidence, and some of the presentations gave an insight into the ways universities and commercial organisations are applying central facilities to fuel and lubricant research.

The University of Edinburgh discussed a collaborative project with Infineum that is exploring the crystallisation behaviour of biodiesel at elevated pressures. Data from these experiments will contribute to the development of crystal modifiers to ensure the performance of modern high pressure diesel injection equipment. Their second talk explained how the increasing availability and decreasing cost of computing power is enabling the structure and dynamic processes, such as surface adsorption and flow, that affect the properties in lubricants to be simulated.

The University of Cambridge presented two projects. The first explained how advances in neutron scattering are delivering insights into the composition of molecules on metal/oil surfaces and the effects of imposing external factors including temperature and shear. The second presentation explored the use of a range of physical chemistry techniques to assess the effect of water on engine oil additives.

Understanding how additives protect the engine at the most fundamental level is essential. Experiments at Diamond are helping to develop more effective components to improve fuel and lubricant performance, help engines last longer, and deliver improved efficiency.

David Collins received the Infineum-Diamond Early Career Research Prize for his work on sheet metal ductility

David Collins received the Infineum-Diamond Early Career Research Prize for his work on sheet metal ductilityDuring the event the Infineum-Diamond Early Career Research Prize was presented to David Collins, doctoral student in the Department of Engineering Science, University of Oxford.

David, who has been working with BMW-MINI, is looking at the ductility of sheet metal used in manufacturing. By stretching the material in new ways, he is looking to develop novel manufacturing processes that will help to make more streamlined cars.

To better understand the material’s behaviour during a hypothetical manufacturing process, David designed and built bespoke testing equipment that can subject material to arbitrary strain-paths. Using Diamond’s Joint Engineering, Environmental and Processing beamline (I12) he has been able to study how the properties of steel change as its atoms are altered. Exploring the effects of deformation on steel as it occurs at the atomic level has the potential to create stronger, more streamlined and more geometrically complex steel structures – something that will be of great benefit to the automotive industry.

This is a great example of research at the interface of industry and academia and of the ways world class science can be applied to real world issues

A growing and prospering population with an increasing appetite for personal mobility creates concerns about future energy supply and emissions levels. The advantages of co-engineering hardware and fluids are clear. Gaining fundamental insights into the behaviour of systems and components at the finest detail is essential to ensure the solutions developed for future mobility will be able to meet global air quality and sustainability expectations.

Some of the challenges our industry faces are so complex that they can only be addressed via collaborative projects that use advanced scientific techniques.

The ICAR event enabled attendees to consider different perspectives and share the ideas and experiences gained from using the facilities available at Diamond. In our view this approach is essential to ensure the development of step-out technology solutions to future environmental and technical challenges.

By helping to forge new relationships ICAR has sparked future collaborations that will generate new developments to help meet our energy and mobility requirements out to 2050 and beyond.

Based on the articles you've read

Sign up to receive monthly updates via email