Driveline

Rising demand for DCT fluids

09 December 2025

01 October 2024

Infineum develops new e-fluid test screeners to explore critical performance requirements

In the passenger car market, powertrain electrification is the technology option of choice for most OEMs looking to decarbonise and deliver improved vehicle efficiency. This is driving growth in the use of dedicated hybrid and electric vehicle transmissions. However, these systems require specialised fluids to ensure their complete protection. Insight explores how newly developed test screeners are helping our technologists get deeper insights into e-fluid performance in many of the critical areas.

As OEMs work to meet regulatory and consumer pressures to decarbonise, the number of hybrid and battery electric vehicles in the passenger car market is growing. This expanding electrified vehicle parc needs bespoke e-fluids, that provide traditional transmission fluid properties and meet new e-specific requirements.

Infineum has been working on e-fluid test developments in some of the most critical areas of protection

Meeting all of these requirements must also be carefully balanced with the need to optimise transmission performance and protection. This is particularly the case in today’s lower viscosity environment, which means new considerations must be applied to component selection when formulating fluids for these applications.

As leaders in driveline additive technology, Infineum has invested in the development of new test screeners to assess the performance of new step-out technology for e-fluid formulations in the critical areas of material compatibility, scuffing and aeration.

Placing motors into the transmission means a number of materials are being introduced that are significantly different from those used in conventional architectures. For example, the copper wire and connections are susceptible to corrosion, which can lead to electric current leakages or to a short circuit in the transmission.

A dedicated test cell allows the corrosion mechanism

to be visualised live

This is why many OEMs see copper compatibility as the most important e-fluid design parameter.

While energised copper corrosion tests exist, multiple testing parameters can lead to test result variability. In addition, interpreting the results obtained from these complex tests requires a deep understanding of corrosion mechanisms.

These challenges led Infineum to develop an oil immersed energised corrosion test to screen technology to ensure good copper compatibility. This comprises a dedicated test cell that allows the corrosion mechanism to be visualised live.

This new rig is helping us to better understand some of the parameters impacting corrosion and the ways corrosion progresses. These insights will be helpful in developing advanced e-fluids capable of delivering the required level of protection.

Effective antiwear additives combined with extreme pressure (EP) additives can be used to mitigate scuffing in the latest transmission systems. However, EP additives with active sulphur have the potential to cause material compatibility concerns. This means a fine balance of chemistries is needed when formulating e-fluids to ensure gear scuffing is prevented while also ensuring materials compatibility.

The FZG is a test used widely in the industry to assess scuffing performance. However, the test parts used, quantity of test fluid and effort required means they are expensive to run. These challenges led Infineum to develop a screener test that would be a simpler, faster and less expensive way to assess antiwear and EP components before full FZG assessment.

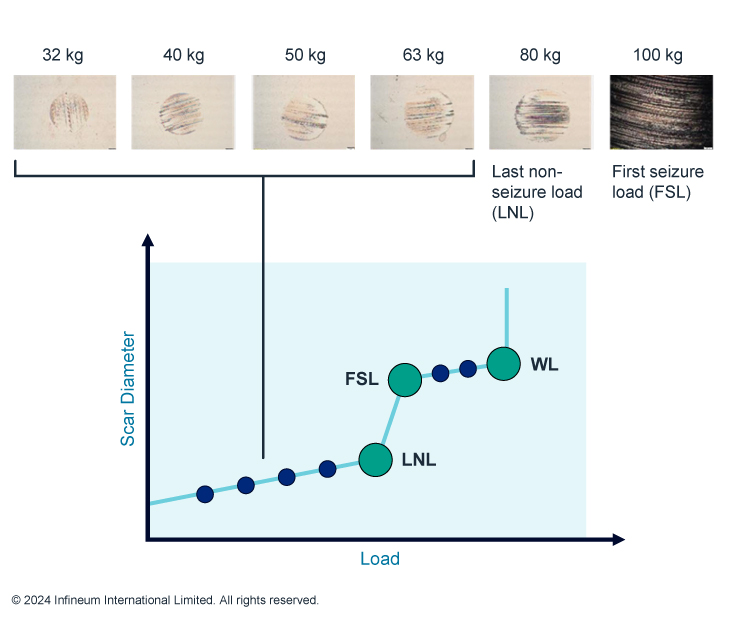

The 4 ball EP test (ASTM D2783) is used to assess oil EP performance and, as in FZG, the load is stepped up until balls begin showing adhesive wear (first seizure load FSL) and run until they are welded together. Good correlation was observed between the FZG Failure Load Stage and 4 Ball EP test results with a model that included the last non-seizure load (LNL) and the area of the scar at the FSL.

Modified 4 ball extreme pressure test, run at loads lower than LNL

Running a modified 4 ball EP test at loads lower than LNL, provides a systematic approach to studying tribofilms as a function of load, composition and coverage. We have already screened hundreds of oils and gained insights into the correlation between tribofilm and scuffing performance and the impact of friction modifier and other additive selection.

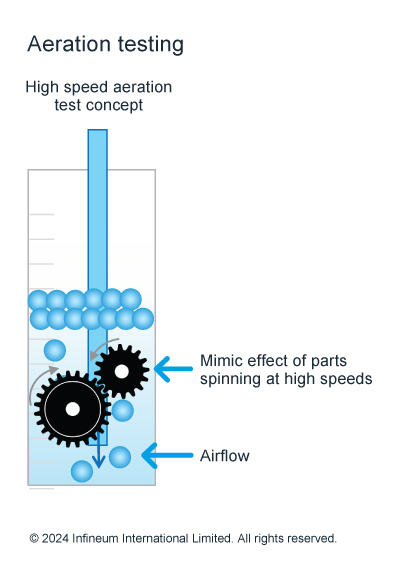

Test mimics the effect of parts spinning at extremely

high speeds under shearing/churning

With new e-gearboxes running at extremely high speeds (>20,000rpm), aeration is a critical performance parameter for e-fluids. Using the existing ASTM D892 and D6082 foaming test as a starting point, our objective was to mimic the impact of parts spinning at speeds of up to 27,000 rpm and to add in a high speed shearing and churning effect to simulate the aeration caused by parts spinning at these very high speeds. Automation and video capture enable us to ensure heating and timing accuracy.

The newly developed, fully automated, High Speed Aeration Test (HSAT) has been used to assess the impact of fluid viscosity, base stock, viscosity modifier type, treat, ageing, anti-foam chemistry etc. and viscosity modifier selection on aeration. Using the HSAT on a number of test samples and commercially available fluids has given us a deeper insight into their aeration performance than would have been possible using the conventional ASTM test.

As leaders in driveline additive technology and e-fluid development, Infineum has invested in developing new testing methods to provide insights into critical performance areas. The deeper understanding of materials compatibility, scuffing and aeration is helping us to develop step-out technologies that will offer advanced protection to electrified transmission systems.

Following on from these laboratory tests, our advanced e-fluids are tested in real-world conditions.

We have already completed almost three million kilometres of field trials across the globe - testing our extensive e-mobility product portfolio in a wide range of hybrid and electric vehicles.

For more details on our dedicated e-mobility products, tailored for every type of electrified transmission application, please contact us here.

Sign up to receive monthly updates via email