Marine engines

OEMs outline challenges ahead

08 December 2025

Please note this article was published in May 2013 and the facts and opinions expressed may no longer be valid.

06 May 2013

Differentiated performance without reprotoxicity labelling

Infineum has developed a component that will allow marine lubricant formulators to meet performance goals, exclude reprotoxicity labelling under the Global Harmonised System, and which offers the possibility for product differentiation.

The progressive introduction of REACH, the European Commission Regulation No 1907/2006 on chemicals and their safe use, and the establishment of a Globally Harmonised System of Classification and Labelling of Chemicals (GHS) have been the drivers for significant change in the chemicals industry.

REACH, which deals with the Registration, Evaluation, Authorisation and Restriction of Chemical substances, aims to improve the protection of human health and the environment through the better and earlier identification of the intrinsic properties of chemical substances.

The law, which entered into force in 2007, replaces a number of European Directives and Regulations with a single system designed to streamline and improve the previous legislative framework on chemicals of the European Union (EU).

REACH places greater responsibility on industry to manage the risks from chemicals and to provide safety information on the substances.

Manufacturers and importers are required to gather information on the properties of their chemical substances, which will allow their safe handling, and to register the information in a central database.

This huge piece of legislation impacts companies who manufacture or use chemicals in the EU or those wishing to import chemicals into the region.

The GHS was created by the UN to remove confusion about the ways in which hazardous properties of chemicals are identified.

It also clarifies how information about these hazards is passed to users through labels or safety data sheets.

The GHS aims to introduce the same criteria for classifying chemicals according to their health, environmental and physical hazards and the same hazard communication requirements for labelling and safety data sheets across the globe.

While the GHS is not legally binding, the international agreement means countries must create local or national legislation to implement it.

Both the REACH and GHS regulations affect the use and labelling of a wide range of chemical substances.

In the marine diesel cylinder lubricants (MDCL) world, one of the chemicals that is impacted by these regulations is Tetrapropenyl phenol (TPP).

Phenate detergents, used in MDCL formulations to provide the necessary high temperature performance, can contain higher levels of TPP, which has been classified as a reprotoxin.

Reprotoxins are substances that are known or presumed to cause effects on human reproduction or on development. By 2015, in certain countries such as the USA, labels on MDCL formulations that contain 0.1% TPP and more will need to carry the appropriate GHS Pictogram and Hazard Class.

Infineum has developed innovative options for MDCL lubricants that present no major harms relevant to marine cylinder lubrication and that remove the need for reprotoxicity labelling.

The development of this new component required years of research. And, collaboration between the chemists and engineers at Infineum has been essential in taking the component from the conceptual stage to a commercial product.

The component has undergone extensive testing in laboratory bench tests and engine tests. This testing was carried out to ensure that, at each stage, the component would not only be something that was fit-for-purpose but would also enable differentiated technology to be developed for the MDCL application.

Formulations based on the new technology have excellent thermal stability, acid neutralisation and lubricity properties.

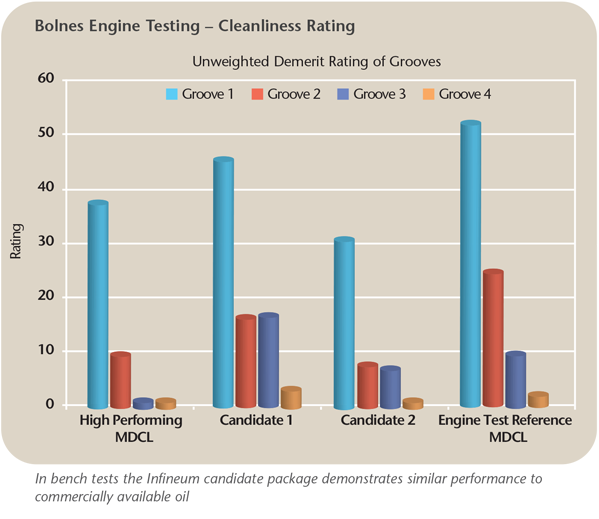

The development phase involved several Bolnes engine tests, resulting in two lead candidates. They were blended as SAE 50 grades, in Group I base stocks and used a combination of the new ashless detergent and sulphonate detergent.

The oils were evaluated against two current high performing MDCL market formulations. Both showed excellent performance in liner wear and piston cleanliness.

The results of this testing programme demonstrate that the Infineum Low TPP technology can replace a high BN phenate additive, which has higher TPP content.

The technology also achieves equivalent performance, while removing the need for undesirable reprotoxicity labelling of the MDCL product, and is currently being proven in a MAN engine in field trials. The development of this new product offers a platform for differentation.

Sign up to receive monthly updates via email