Lubricant trends

Advances in automotive lubricant design

04 March 2025

02 October 2024

Industry watchdogs see increasing industry complexity and incidence of non-compliance with specifications

Industry and OEM lubricant specifications exist so that engine oils deliver the required level of protection over sufficient drain intervals to cars and trucks. It is vital that oil marketers making claims against them ensure their products really do meet all of the stated requirements. Insight Editor, Rose Gill, talks to David Wright, ATIEL Quality Management System Committee Chairman, SAIL Director, Mike Boyer, and Alan Outhwaite, VLS Technical Review Panel Chairman, about trends in lubricant compliance and the work they are doing to maintain a level industry playing field and protect the interests of end users.

The advanced engineering in today’s vehicles requires innovative chemistry to protect it. Developing formulations that meet OEMs’ performance and protection requirements over longer and longer drain intervals, while also helping to improve fuel efficiency, is no easy task. And, it is becoming increasingly challenging as tighter chemical restrictions are introduced.

In Europe, the European Automobile Manufacturers’ Association (ACEA) industry engine oil standards or sequences, provide a set of performance requirements that define oils offering baseline protection for the majority of the European car and truck fleet. These oils, when used as recommended, meet the needs of modern automotive engines and should deliver a good quality lubricant on which marketers, OEMs and consumers can rely. The specifications define a common baseline for lubricant developers. However, OEMs can achieve additional performance and protection, specific to their own engines, via their in-house specifications. In addition, lubricants for other hardware systems, such as large stationary gas and marine engines, rely solely on OEM approvals.

As David Wright from the Technical Association of the European Lubricants Industry ATIEL explains, there is a real difference in the way the specification types operate. “ACEA performance claims are self-certifying, which means companies must satisfy themselves that they can meet the requirements of the ACEA sequences and submit a Letter of Conformance (LoC) to SAIL. Whereas to claim a formal approval against an OEM specification, a product is taken through a series of stages and, on passing, is awarded a formal letter of approval from the OEM. The third way is to use market general technology underpinned by performance test data, which meets the requirements of OEMs but without a formal approval. These ways are very different, and I think that's confusing for some people.”

It is a long and expensive process to formulate oils that meet these quality levels. But, it is essential that oil marketers ensure the claims made on the outside of the bottle accurately represent the oil inside.

David Wright, ATIEL Quality Management System Committee Chairman

A number of organisations and systems are in place, which are all working to improve the quality of lubricants in the marketplace. However, as David continues, it is quite a complex picture.

“ATIEL represents leading European and international engine oil manufacturers and marketers. UEIL (the Union of the European Lubricants Industry) represents the interests of the lubricants industry in Europe, with a focus on SMEs and independent companies. These two organisations, along with our industry partners Additive Technical Committee (ATC), work together to help ACEA develop oil formulations that meet the needs of light-duty and heavy-duty vehicles."

ATIEL’s role is to promote and safeguard engine lubricant quality and our members include most of the major lubricant companies and some leading independents.

David Wright, ATIEL Quality Management System Committee Chairman

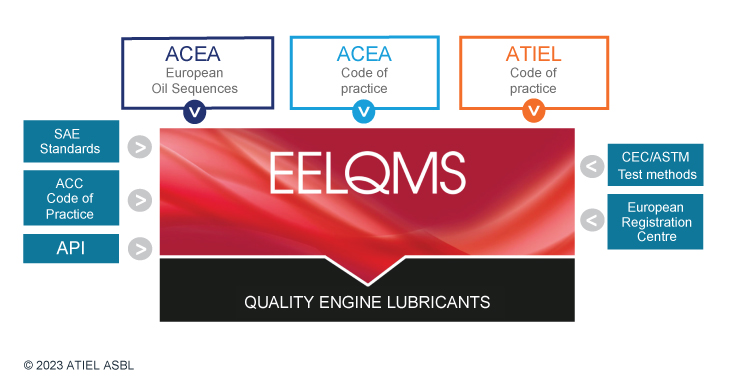

"We draw on their technical know-how to develop formulations that will meet modern emissions regulations and the needs of the latest vehicle engines. Once those formulations are developed we follow through to make sure that anyone making claims against the ACEA engine oil sequences does so in a compliant manner. Over and above ATIEL, sits the European Engine Lubricant Quality Management System or EELQMS.”

EELQMS provides a framework for the development of lubricants carrying industry claims. It was developed jointly by stakeholders from OEMs, lubricant marketers and additive companies to ensure lubricants can meet the technical requirements of the automotive industry.

EELQMS is designed to help lubricant marketers verify the quality of their lubricants and the performance claims being made. It provides a process and structure covering lubricant development and performance validation that sets a level playing field for all stakeholders.

This framework and the jointly developed processes mean end users should be able to trust the quality of the lubricant products in the marketplace. But, there is also a need to monitor products making compliant claims against the ACEA engine oil sequences and OEM specifications – and that’s where the organisations SAIL (Services to Associations and Industry in the Lubricants sector) and VLS (Verification of Lubricant Specifications) come in.

Let’s start with a look at SAIL, a subsidiary of ATIEL, which monitors product compliance against ACEA claims on a global basis. Mike Boyer, SAIL Director, explains what their aims are in terms of checking compliance.

“In our global quality assurance programme our commitment is to test three products from a registered company in a three year period, typically this means at least one product from each registered participant per year, but it isn’t always the case."

We currently have 483 registrants all of whom have a signed LoC, 53% in Europe and 36% in Asia, and this year we are testing around 475 different products.

Mike Boyer, SAIL Director

"We use a 3rd party accredited laboratory to collect the samples from the marketplace. They run 10 different tests on each sample - five physical and five chemical - we also check for correct representation of the ACEA claim.”

In 2023, ATIEL/SAIL sponsored over 4,000 individual tests as part of the Lubricant Marketers’ Letter of Conformance compliance programme. Test reports that identify any non-conformance are anonymised before being reviewed by ATIEL’s Technical Expert Committee. They are then issued to the respective Letter of Conformance scheme participant by SAIL. Corrective actions are always reviewed by the committee before the reports can be closed by SAIL.

Mike goes on the explain about the types of non-compliances and what happens when a product falls short of the sequence or does not represent the ACEA claim correctly. “Some failures are fairly borderline, but we do see some significant non-compliances where there's a good chance that if you put the oil in a vehicle it could do some harm. We have found that generally registered participants are interested in getting it right. When a non-compliance does occur the participant receives a report and, while our role is not to give advice on how to comply, we do ask them what corrective actions they are going put in place to make sure that it doesn't occur again and guide them on what we expect in terms of evidence.”

One trend Mike is seeing in non-compliance is in formulations that combine claims to allow one product to be used in a number of vehicles, which helps end users reduce the number of oils that need to be stocked. “In these oils we find they are designed right on the margins in order to provide protection, film thickness and chemical protection at the same time as trying to provide some benefit in terms of fuel economy improvement."

What we have seen in formulations that combine claims is a higher instance of non-compliance in the High Temperature High Shear (HTHS) test. And, these formulation challenges are seeing it all the way through into products in the marketplace.

Mike Boyer, SAIL Director

In his opinion, Mike says there is some confusion over where the liability of making ACEA claims lies. “If a big supermarket, for example, is selling lubricants it, as the lubricant marketer, is legally responsible for product quality – not their supplier. Now what we are finding is about a third of participants submitted a quality assurance certificate from a third party – which means they are using toll blenders. So, although lubricant marketers might not always be oil experts, they do need to know if their oils meet the ACEA sequences. That’s really essential, because, when a lubricant marketer signs the LoC, it is a declaration by them that the product has been developed in accordance with all of the ACEA requirements. It's not the supplier's responsibility, it's not the technology provider's responsibility, the responsibility lies with you the oil marketer.”

Moving on to look at VLS, a subsidiary of the UK Lubricants Association (UKLA) that launched in 2013. Alan Outhwaite, VLS Technical Review Panel Chairman, gives an overview of this independent organisation that is working to verify lubricant specifications in a number of end-use applications.

“We are focused on our remit of the UK market. Where we differ slightly from SAIL is that while they look at organisations from any region for non-compliance to ACEA standards, we look at, not only automotive engine oils, but any lubricant that is making performance claims against technical specifications and market standards. And, it can be ACEA plus OEM specifications, but it can equally be a gear oil or a metalworking fluid that doesn't have any ACEA connection whatsoever that may make an erroneous claim. So the VLS brief is much broader in terms of lubricant applications.”

Unlike the SAIL QA programme, where an independent party procures samples for testing, Alan goes on to explain how cases are raised for VLS for review. “The majority of the complaints come from other lubricant marketers and manufacturers who come across a product in the marketplace which seems too good to be true, typically on a price performance equation. The organisation does their own testing or a desktop review of the product and if they detect that there's something untoward they'll refer it to VLS. The other type of complaint we've had, only about three or four of all the complaints we've dealt with so far, come from members of the public. It could be garage owners, engineers or mechanics who come across a product and don't understand the claims because they seem to be conflicting, for example a product that claims both high and medium sulphated ash, phosphorous and sulphur (SAPS).”

Alan continues with what happens next. “We have a robust set of practises that have been established over 10 years. When a case is raised, it is anonymised to take bias out of the system and checked to make sure it's valid and then passed to the Technical Review Panel (TRP) for consideration. Anonymisation could mean someone on the TRP may make judgements on their own products, which is absolutely right! However, when we look at the characteristics of a product or specification and the range of claims, if somebody were to recognise their own product, they drop out the investigation immediately and take no part in the debate or decisions relating to the product.”

VLS is seeing an increase in the number of complaints and in the diversity of products, Alan confirms. “Our case numbers are increasing from 11 in 2022, we had 19 in 2023 and already 17 in 2024.”

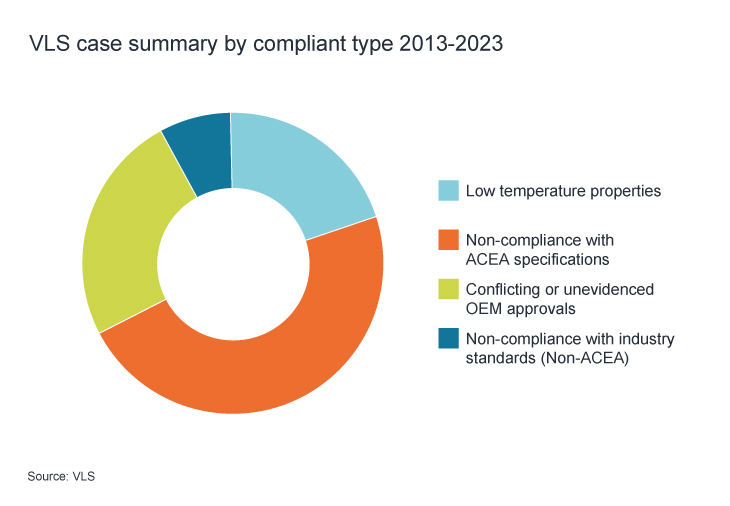

From 2013 to 2023, VLS has investigated 100 cases of complaints regarding lubricants.

Alan Outhwaite, VLS Technical Review Panel Chairman

“While about 70% have been for passenger car oils, we are now seeing a wider range of products, for example metal working fluids, tractor hydraulic fluids and hydraulic oils coming across our desks. We have progressed these using our processes and reached very satisfactory conclusions. I think this uptake is testament to the fact that our processes are becoming more well known and people are now confident about VLS. We also want to help educate the industry, and the guidance we have published that's available on our website is designed to help lubricant manufacturers make claims on their oils.”

VLS sees four main topics in the cases they have assessed, non-compliance with stated specifications being the most frequent cause of complaint.

Alan goes on to explain how things are escalated when non-compliance is detected. “We publish the case on the VLS website and in Lube Magazine – I have to stress that when case details are published, the complainant's name is never made public. Whenever we come across a complaint where the lubricant marketer is reluctant to engage with us we have the option of escalating the case to Trading Standards Authorities who can ask for improvements to be made – although most companies will take corrective action to resolve the issues before it escalates to this point.”

The complexity within the lubricants industry is increasing, David explains how this makes the work of VLS and SAIL more important than ever before. “Lubricants are very complex chemical products and, around the world, they are becoming even more complicated. End users might not necessarily understand all the standards lubricants are developed to, so we are trying to protect their interests. However, it is important to stress that we don't ever say a lubricant is ‘fit for purpose’, we just look at compliance against stated performance claims and technical specifications.”

Alan agrees, “The industry is getting incredibly competitive with lots of different players and it's meant to be a level playing field."

People playing fast and loose with performance claims is not fair on anybody and certainly not fair on the end user who may be exposed to risk through using a product not meeting the right specification for the application.

Alan Outhwaite, VLS Technical Review Panel Chairman

From a SAIL perspective Mike sees three main groups that really benefit from the product compliance monitoring programme. “OEMs need to know that appropriate quality engine oils will be available in all the markets they serve, trade/workshops need assurance that inadequate lubricant performance will not lead to warranty claims and consumers need confidence in the quality of the products being used in their vehicles. ACEA lubricants have a truly global reach, the programme we manage encourages greater compliance right across the industry through continuous monitoring of lubricant quality in the global marketplace.’’

Infineum is supportive of the services VLS and SAIL provide in ensuring lubricants deliver the performance that is claimed, trying to maintain a level industry playing field, and helping to protect the interests of end users.

Sign up to receive monthly updates via email