Commercial vehicles

ACEA HD Sequences released

22 January 2025

10 December 2024

The Cummins ISB viscosity test is ready to replace the Mack T-11 for soot related viscosity increase

The Mack T-11 engine test has served the industry well over the past 21 years as the test for measuring soot related viscosity increase. Now it has reached its last batch of hardware, which means a new test is needed for the upcoming PC-12 heavy-duty engine oil category. Infineum Engineering Leader, Jacob Goodale, talks about the test development, how it differs from its predecessors and the timeline for its introduction into PC-12.

The Mack T-11 engine test has long been used to test an oil’s ability to maintain viscosity control with exhaust gas recirculation (EGR) derived soot combustion in diesel engines. Its replacement is one of the biggest changes in the new PC-12 category development.

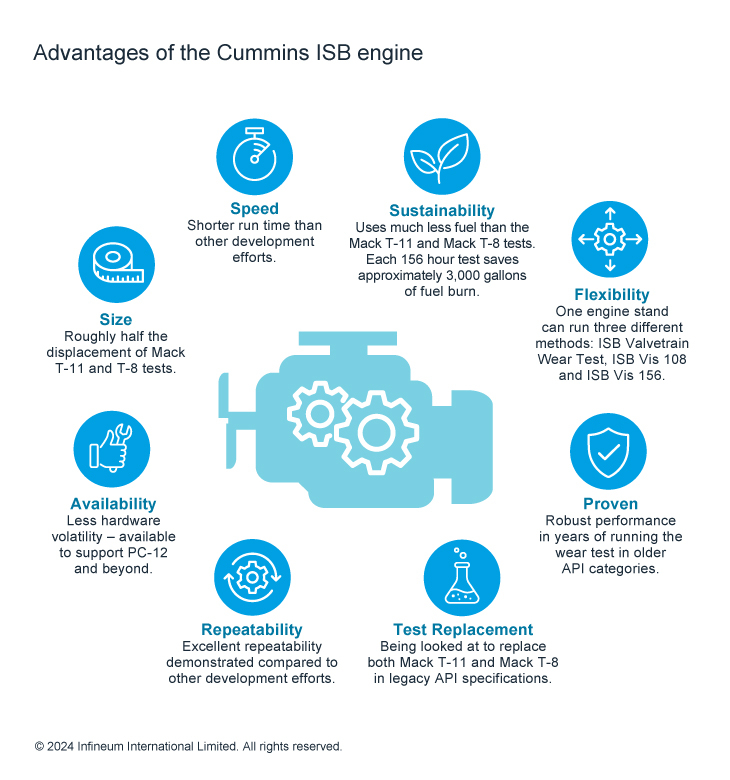

The American Petroleum Institute (API) New Category Development Team (NCDT) kicked off a Mack T-11 Replacement Task Force in mid-2022. The group, formed from a number of interested parties, including OEMs, additive companies, oil marketers and industry bodies, set out to find a suitable replacement for the Mack T-11 and Mack T-8 engine tests. Initially two potential engine platforms – Cummins ISB and ISM - were proposed as replacements. After considerable time and effort, the Cummins ISB engine test platform has been chosen over the Cummins ISM to replace the Mack T-11. In addition to lower fuel consumption, the Cummins ISB viscosity test offers the possibility of reusing engines that are no longer suitable for wear testing, thus allowing the industry to make better use of resources and supporting a more sustainable testing environment for the future.

Infineum has been heavily involved in the development of the new Cummins ISB soot related viscosity increase test, working collaboratively in the background with Southwest Research Institute (SwRI). Infineum drafted a modified set of operating conditions and ran a development test focused on reducing total run time from the originally proposed 252 hours (current Mack T-11 test length) ISB viscosity test. The shortened version of the test demonstrated acceptable performance and a significant step forward in sustainability, and was known to NCDT as the 20 kg/hr fuel rate procedure.

Following its selection in March 2023, four participating test labs ran shakedown and proof of performance testing. Issues arose with mild data on known performing oils. Infineum and SwRI drafted another procedure change focusing on increasing the fuel rate from 20 kg/hr to 25 kg/hr and re-ran a known ‘good oil’ and a ‘poor oil’ that had lost discrimination during the mild phase. The boundary condition change restored the expected performance of both oils highlighting that this was the correct path forward for the Cummins ISB viscosity test.

In early 2024, despite requests to delay the start of the precision matrix, the Task Force voted to continue forward with the 25 kg/hr fuel rate procedure. The precision matrix, which ran a total of 20 tests across four labs, completed in June 2024. In September 2024, the reference oil targets and standard deviations were created and the lubricant test monitoring system definitions were completed.

It has taken over two years, but the test development has in the main been a smooth process.

All participating labs have hardware and tests stands and can now run the Cummins ISB viscosity test. The familiarity with the hardware and engine architecture was a key factor in the reduction of the test development timeline. However, key delays have also come from various severity concerns along the way.

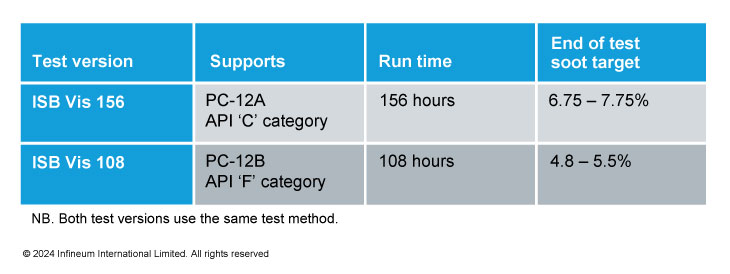

The final test is split into two distinct methods to support the diverging soot handling targets of the two PC-12 categories.

The Cummins ISB engine has a number of advantages which make it an ideal test platform.

Initial data generated in the Cummins ISB viscosity test show that it is just as challenging to pass as the Mack T-11 and Mack T-8 engine tests. However, some oils do not perform as well in the new test as in the older Mack engine tests. The limits, to be agreed at the end of the technology demonstration period, will set the bar for just how ‘formulation defining’ the test will actually be. But, regardless of these limits, the test has proven to be very challenging.

The test has checked off many key milestones and has a few more to pass before development is completed. Key remaining milestones include completion of the base oil interchange and viscosity grade read across (BOI/VGRA) matrices, finalisation and acceptance of the ASTM method, limit setting post technology demonstration period and acceptance into the American Chemistry Council (ACC) Code of Practice.

Great progress has been made on delivering these milestones, with the BOI/VGRA matrices scheduled to be completed in early 2025 and we expect the test procedure to be in review with the ASTM facilitator by YE 2024.

All this headway and continued activity means the new Cummins ISB viscosity test has an extremely high likelihood of making it into the PC-12 category. The method has shown to be robust at discriminating the different quality of oils for each PC-12 performance category as well as showing very similar performance to the Mack T-11 test when running the same reference oil.

Once it has been fully accepted, the Cummins ISB viscosity test is likely to be used to replace not only the Mack T-11 for PC-12 but also the Mack T-11 and Mack T-8 in legacy categories.

The Mack T-8 reference fluid shows expected viscosity increase vs soot in the 108 hour test, making this the likely successor to the Mack T-8 in legacy categories. However, it will be the job of the API Category Life Oversight Group (CLOG) to define how it can be used as a replacement.

Our close involvement with the development of this new test procedure means we are well positioned to develop formulations that will help to protect current, past and future hardware from excess viscosity growth from soot in the oil. With PC-12 on the horizon, Infineum is ready to help support your needs with robust, balanced formulations.

Sign up to receive monthly updates via email