Marine engines

OEMs outline challenges ahead

08 December 2025

Please note this article was published in May 2013 and the facts and opinions expressed may no longer be valid.

06 May 2013

New Infineum medium speed engine oil formulation in highly refined base oil

Using highly refined base oils to formulate marine and large engine oils offers a number of benefits. But, their low solvency also presents challenges to the formulator. Laura Gregory, Marine and Large Engine Lubricant Developer, explains how Infineum has overcome the issues, retained the benefits and gained OEM approval for Group II formulations.

Lubricant formulations for use in four-stroke marine and stationary power generation engines, contain a high proportion of base oil. This means both the intrinsic properties of the base oil and the way it interacts with the additive system can significantly influence the performance of the finished lubricant.

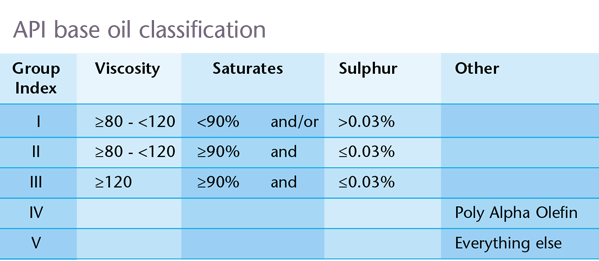

The American Petroleum Institute (API) uses viscosity index, saturate and sulphur content to categorise base oils.

Lubricants for medium speed engines have predominantly used Group I base oils, which have the lowest saturates and highest sulphur content.

Until recently there has been no technical or commercial driver for the use of base oils of alternative quality.

However, increased demand for higher quality Group II base oils from the automotive industry means Group II base oil capacity is increasing, while Group I production is in decline.

This high availability of Group II has the knock on effects of driving the price of Group II down and leaving Group I in short supply as plants close and investment in its production ceases.

This change at the refinery means these more refined base oils are being used in a wider range of applications. The medium speed engine oil market is no exception.

Today we find Group II base oils are increasingly being used as a diluent system, which brings a whole new set of advantages and challenges.

Group II base oils are generally considered to be of higher quality than Group I and can deliver improved performance to large engine lubricants.

Because the hydrocarbons are virtually all saturated they can deliver improved resistance to oxidation, which reduces deposit formation and maintains viscosity levels for longer periods.

Lower sulphur and nitrogen levels in the base oil mean SOx and NOx emission levels arising from lubricant consumption are reduced.

Those Group II base oils with a higher viscosity index can maintain a thicker oil film at higher temperatures, which decreases the potential for mechanical wear. However, their low solvency has a major adverse effect that challenges their use in medium speed engine oil applications.

Most medium speed engines run on heavy fuel oil (HFO), which contains relatively large concentrations of polyaromatic hydrocarbons (or asphaltenes). During engine operation, partially combusted asphaltenes can migrate into the oil.

Lubricants must be able to handle asphaltenes and prevent them from being deposited on colder parts of the engine as ‘black sludge'.

Piston undercrown deposits can also form, and these are a particular concern because they can prevent the lubricating oil from transferring heat away from the piston crown. This will eventually result in high temperature corrosion of the piston crown and lead to severe engine damage.

Oils formulated in Group I base oils and using high performance salicylate technology have proven their ability to handle asphaltenes at levels typically experienced in normal operation of medium speed engines. This means they can control deposits and black sludge, protect the engine, extend oil drain intervals and reduce operating costs.

However, for lubricants formulated with Group II base oils a new additive system is needed to ensure engine cleanliness is maintained, because the lower solvency of Group II base oils means they are less able to handle asphaltenes.

Research and development work to closely examine the behaviour of the asphaltenes led to the development of a new Infineum salicylate-based additive package for use in a range of Group II base oils.

A new salicylate-based additive package offers improved asphaltene handling in Group II base oils

This offers improved asphaltene handling capabilities to prevent black sludge and piston undercrown deposits, without compromising the advantages of longer drain intervals and cleaner engines that these base oils can deliver.

Infineum has carried out a field trial on a lubricant formulation based on the new additive system in a Class 1A cargo vessel, with 9860 dwt capacity running on a single Wärtsilä 6L38B engine.

After the trial, which ran for more than 4,400 hours, the end of test inspection showed that all the engine parts lubricated with the test oil were in good condition with no build-up of piston undercrown deposits. As a result of this work Infineum has achieved an OEM approval for a lubricant formulated in Group II base oils.

Through this work, Infineum has been able to demonstrate that by using high performance additive technology blending in both Group I and Group II base oils is possible with no detriment to engine operation.

These new marine and large engine lubricant formulations control deposits and black sludge, protect the engine, demonstrate no detriment under normal working conditions, extend oil drain intervals and help to reduce operating costs.

Sign up to receive monthly updates via email