Fuels

Reported sludging incidents rise

04 November 2025

09 May 2023

Severe winter field trials using hydrogenated vegetable oil

In a transportation sector looking for ways to decarbonise and meet sustainability goals, the use of renewable diesel fuel can be an easy step in the right direction. However, until recently, its performance in real vehicles under extremely low temperature conditions was little understood. Tatsuya Ichijo, Infineum Fuels Technical Sales Account Manager, reveals the results of recent field trials during extremely severe winter conditions in Japan, which demonstrate how some of the concerns about the use of renewable fuels can be overcome.

Renewable diesel fuel, also known as hydrogenated vegetable oil (HVO), can be produced from a wide variety of sustainable raw materials including vegetable oils, waste oils and residual fats. Not only is the resulting fuel fossil and fatty acid methyl ester (FAME) free but it also has other advantages vs. more conventional products, in that it has the same chemical structure as fossil fuel with good stability against oxidation and hydrolysis. And, unlike FAME, HVO can be blended with fossil diesel fuel without limitation according to the EN 590 standard. All these factors mean interest in its use, especially in Europe, is growing as customers seek cleaner, sustainable and more environmentally friendly fuels.

While HVO can generally be used in vehicles in the same way as conventional diesel, it has a very different n-alkane distribution, containing a large amount of C16/18 n-alkanes, which are intrinsically derived from the chemical structure of the raw materials. In addition, the feedstock oils and level of isomerisation impact its composition and affect the final fuel characteristics, especially related to its cold flow properties (for example cloud point). However, despite the fact that HVO has started to be commonly used in the market, there is very little understanding of its cold flow properties in real vehicles under real driving conditions in cold climates. These uncertainties regarding its performance made HVO the ideal candidate for our 2023 winter field trials.

Infineum regularly carries out field trials in Asahikawa-city, Hokkaido on Japan’s north island during the coldest months, when average minimum temperatures can plummet to -13°C.

The Japan winter field trials provide a great opportunity to test our products in the harshest conditions, rather than relying solely on laboratory tests.

The questions we wanted to answer regarding HVO use were:

Taking our first question, it’s well known that, for a conventional diesel fuel, CFPP bench test results can provide a reasonable indication of the performance we can expect to see in real vehicles. However, there is no evidence to ensure this test can give the same confidence in the case of HVO-diesel blends. One of the key goals of this year’s field trial was to investigate the correlation between CFPP results and real vehicle operability using HVO fuels in the hope to confirm that reasonable protection assurance can be given by running the CFPP test.

We also wanted to confirm that cold flow improver additives are effective when using HVO in real vehicles. In addition, the trials provided an excellent opportunity for us to assess the performance of a newly developed Infineum cold flow improver (CFI) additive formulation in real vehicles, having already confirmed its capability to improve the CFPP bench test results of HVO.

For the field testing, three HVOs with low, moderate, and high isomerisation, with cloud point ranging from -30°C to >15°C, were prepared. Four fossil diesel fuels manufactured in Europe, Korea and Japan, and one FAME were prepared to blend with the HVO. Two CFIs, selected from our conventional product slate, and two advanced CFIs, newly developed for HVO, were selected for the trials. The blending ratio of HVO, fossil diesel, FAME and CFI were chosen to ensure the CFPP of the blends would be between -9°C and -25°C, which is roughly consistent with the expected daily minimum temperature in Asahikawa. Accordingly, one pure HVO, five HVO-diesel blends without CFI, and ten additised HVO-diesel blends were prepared and tested in three Hino Dutro TKG light commercial trucks.

Fuel preparation, which takes place the day before the trials, involves flushing the fuel line and fuel tank with the test fuel before filling the tanks. As the ambient temperature falls overnight, the test fuel cools down, resulting in the formation of wax crystal in the fuel line and fuel tank. In the early morning, when the lowest temperature can be expected, the testing begins and two vehicle operability parameters: startability, to assess fuel supply pump filter blocking, and drivability, to examine main filter plugging are assessed.

Engine startability is affected by the wax formed and retained in the fuel line. This wax can block the supply pump filter, that protects the high pressure pump, when the engine is started. On the other hand, drivability is affected by the wax formed in the fuel tank. Here, wax is carried to the main filter, where it gradually accumulates as the vehicle is driven. Unless the wax is re-melted as it is heated by the heater or by returned fuel from the engine, the main filter will be plugged.

Startability data

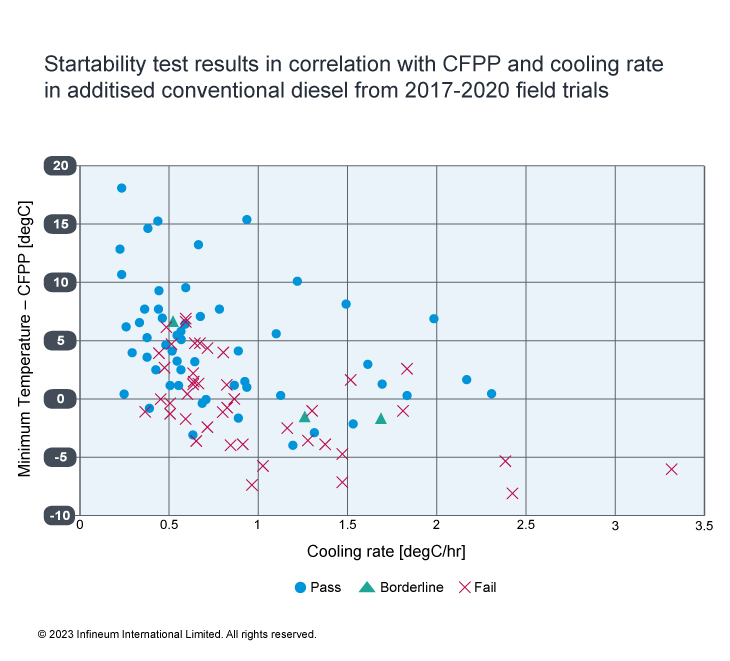

The startability test assesses if the engine will continue to run following first ignition. When using conventional diesel fuels, startability test results obtained in our previous winter field trials running Hino Dutro trucks have supported the correlation between CFPP results and startability testing of real vehicles.

The chart above shows the startability test results of the vehicles running on conventional diesel fuel treated with cold flow improvers from 2017-2020 field trials. The X-axis and Y-axis respectively indicate the cooling rate which the fuel experienced overnight and the difference between the minimum fuel temperature overnight and CFPP value of the fuel. So, we would expect to see a transition from passes to fails around 0°C for good correlation between CFPP and real world operability. The chart indicates that most of the results above 5°C (i.e. minimum temperature in overnight cooling was >CFPP+5°C) are passes and most below -5°C are failures. Although some fuels failed above their CFPP, most of these samples experienced slow cooling rate (<1°C/hr) while the cooling rate during CFPP testing is very fast (around 40°C/hr). Because wax crystals tend to be bigger at slower cooling rate, these fuels were supposed to generate bigger wax crystals than those under CFPP testing conditions, leading to fail results which were not predicted by CFPP testing.

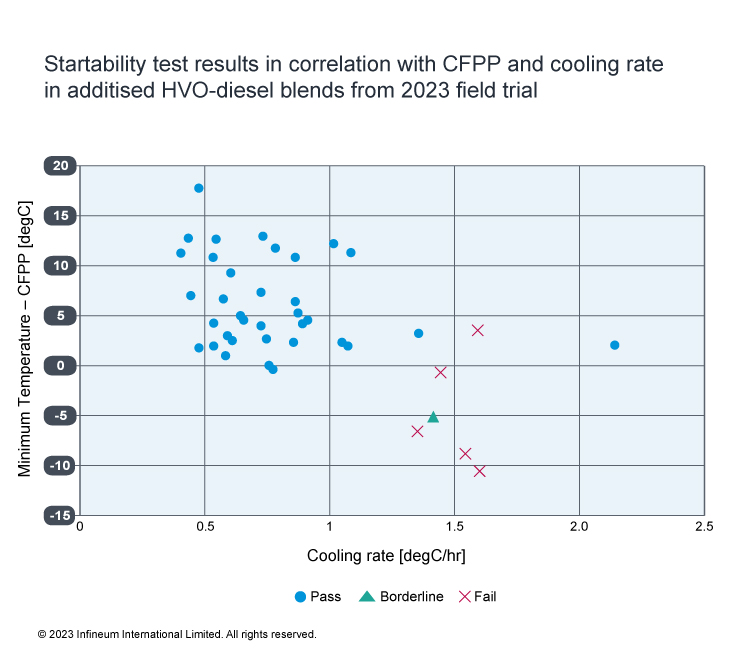

Our 2023 testing was designed to assess the reliability of CFPP vs. real vehicle testing using HVO – conventional diesel fuel blends – again using Hino Dutro trucks.

Overall, the trends were similar to the previous data obtained for conventional diesel and none of the data obtained would lead us to doubt the relevance of using CFPP for HVO evaluation. We can actually see the transition from passes to fails around 0°C in this chart. However, there is insufficient data, especially below zero degrees, to draw a definite conclusion on the reliability of CFPP for HVO, which we hope to obtain in future field trials.

Drivability data

The drivability test determines if the vehicle will continue to run at 50 km/hour throughout the duration of the test. Performance is mainly affected by wax crystal size, shape and content. If the fuel has small sized or needle-shaped crystals, a porous wax cake forms on the filter. This allows fuel to go through the wax cake and makes it easier for the wax cake to re-melt, resulting in the increased tolerance of the filter to wax.

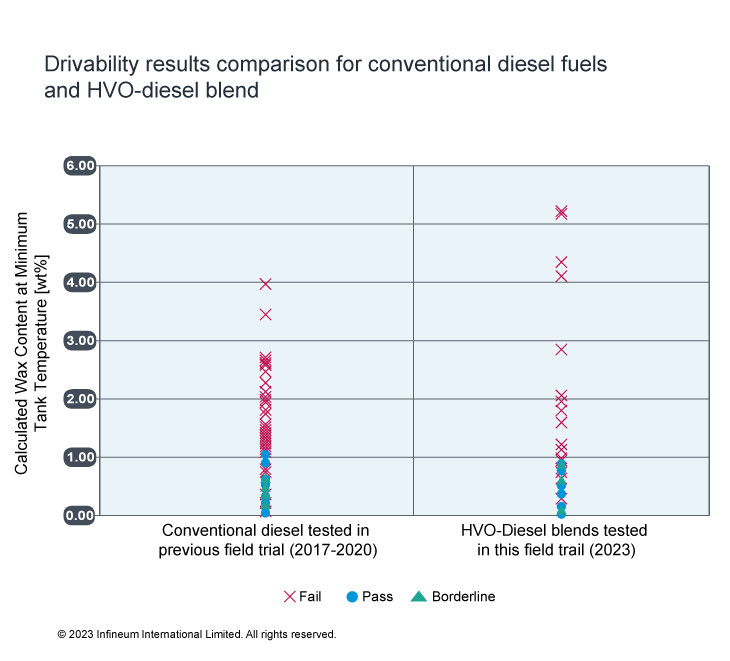

In this analysis we have compared the drivability data previously obtained for conventional diesel against this year’s HVO-diesel blend results, with the data in the chart below arranged according to wax content at the minimum temperature the fuel experienced overnight, regardless of wax crystal size and shape.

For the conventional diesel fuels tested, it is evident that below 1.0 wt%, even if fuels have the same amount of wax content, they can give pass, borderline or fail results according to their wax crystal size and shape. The wax crystal size and shape can be modified by using CFI, but the CFI does not impact the wax content. Therefore, this figure indicates, if the wax content is less than 1wt%, drivability of this vehicle can be improved by using CFI.

However, above 1.0 wt%, all samples returned fail results, which means the filter of the vehicle is unable to tolerate wax content above 1 wt% regardless of the wax crystal size and shape, and CFI use. Therefore, in order to ensure the drivability of this specific vehicle, it is important for fuel supplier to keep wax content below 1 wt% at the minimum temperature at which the fuel is supposed to be used.

The results for the HVO-conventional diesel blend showed the threshold of vehicle drivability at the same wax content (1.0 wt%) as conventional diesel. This result supports an indication that the wax cake formed from HVO may be dealt with in the same manner as conventional diesel when we discuss the drivability of real vehicles.

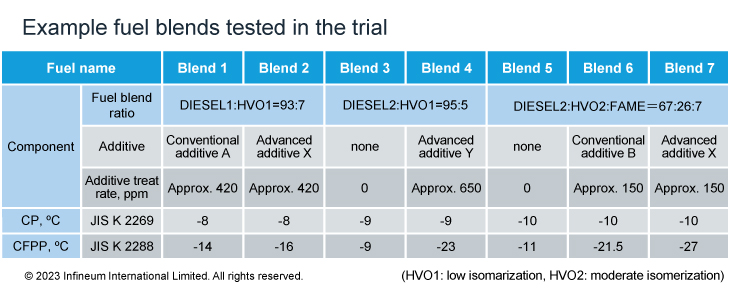

Clearly the field trial testing conditions depend on daily weather. In order to determine a temperature threshold of pass/fail results of a specific fuel, the ambient temperature needs to be just around the threshold. Unfortunately, this year, the ambient temperature fell below -20°C less often than expected, and the actual minimum temperature of the testing day was frequently inconsistent with the temperature we had predicted on the day before. However, the seven HVO-diesel blends shown in the table below successfully provided useful data related to the effectiveness of CFI to improve real vehicle operability of HVO.

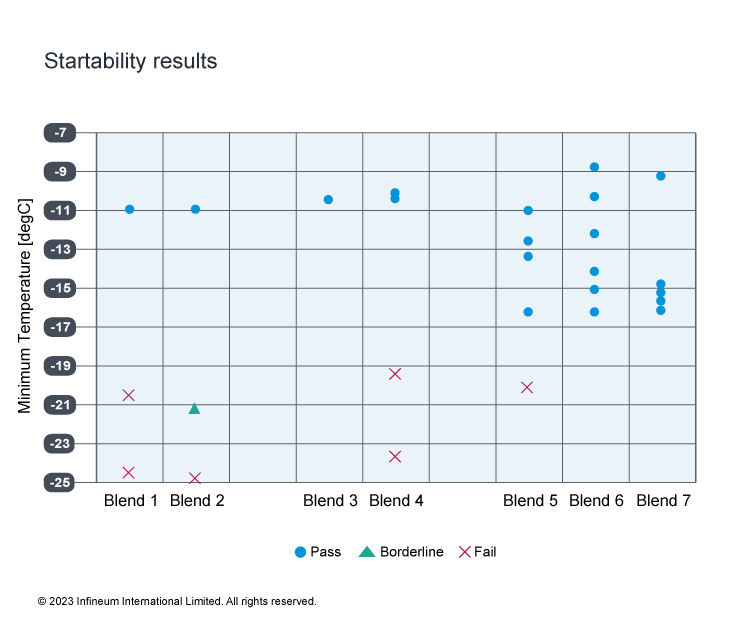

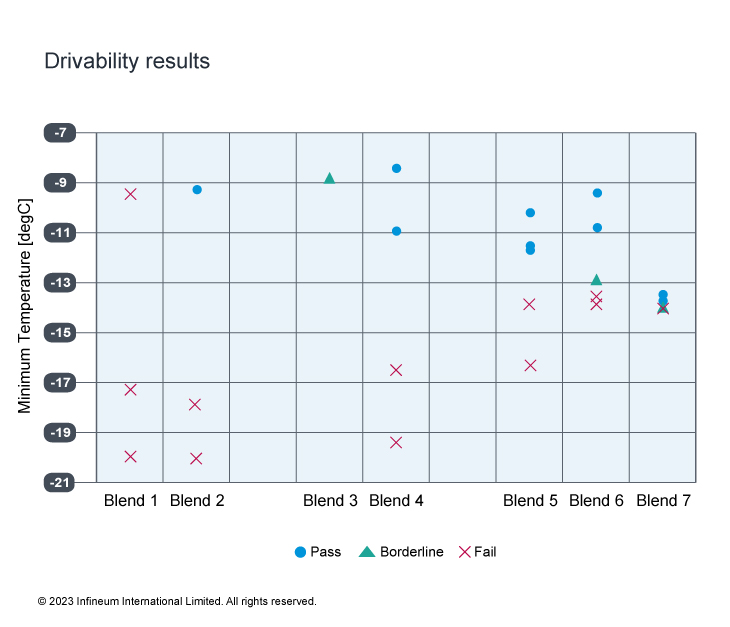

The two charts above show the startability and drivability test results of Blend 1 to 7. The Y-axes indicate the minimum temperature which the fuel experienced overnight.

Comparing the test results of Blend 1 and 2 clearly showed that, in both startability and drivability, the advanced additive X has superior performance vs. the conventional additive A, which is consistent with the prediction from CFPP bench test results of these blends. Blend 2 gave us a ‘borderline’ result in the startability test at around -21°C and a ‘pass’ result in the drivability test at around -9°C while Blend 1 failed in both tests at corresponding temperature respectively.

Similarly, a comparison of Blend 3 and 4, and Blend 5 to 7 showed the advantage of our newly developed advanced additives Y and X over both unadditised and the conventional additive B in drivability testing.

Overall, we confirmed CFI’s capability to improve real-world operability of vehicles at low temperatures when using HVO, and the advantage of our newly developed CFI formulation over our conventional formulation.

While temperatures were not as low as expected in this year’s trials, useful data were generated allowing comparison of non-additised, conventional additive, and new additive technology when using HVO blends in real driving conditions.

We were able to gain some insight into the usefulness of CFPP for HVO as an indicator of the performance that can be expected in real vehicles. However, there is insufficient startability data, especially below zero degrees, to draw a definite conclusion. It is possible to say that the trends were similar to results for conventional diesel and thus do not rule out the use of CFPP for HVO. However, this is something we plan to continue to explore in future field trials.

In addition, we learnt that the wax cake formed from HVO may be dealt with in the same manner as that formed when running vehicles on conventional diesel fuel.

We were able to confirm that our newly developed CFI formulation can outperform conventional CFI in startability and drivability testing.

Infineum will continue to assess real vehicle performance of HVO blended with conventional fuel and pure HVO using alternative HVO sources in future winter field trials in Japan.

Click here to sign up to receive Insight updates to your inbox to stay up-to-date with our progress.

Sign up to receive monthly updates via email