Lubricant trends

Advances in automotive lubricant design

04 March 2025

Please note this article was published in June 2013 and the facts and opinions expressed may no longer be valid.

01 June 2013

New viscosity modifier delivers both fuel economy and engine durability

With vehicle CO2 reduction high on the industry agenda, fuel economy improvement has become one of the key drivers for change in lubricant technology. However, in this quest for fuel economy gains passenger car motor oil formulators must ensure they do not sacrifice engine protection.

Carbon dioxide (CO2) emissions legislation is being introduced or tightened right across the globe, which means industry attention on fuel economy (FE) is at an all time high. Europe has introduced a 130g CO2/km fleet average limit by 2015, and a proposal to cut average emissions from new cars to 95g CO2/km in 2020.

The US will maintain a CAFE scheme with a proposed limit of 54.5 mpg for cars and light trucks by 2025, while in Japan a CAFE style scheme is on the horizon, which would raise automotive FE standards 24% by 2020 vs. 2009.

Lubricant derived fuel economy improvements are very attractive to OEMs

Lubricant derived fuel economy improvements are very attractive to OEMs

A huge array of hardware changes are being implemented on conventional diesel and gasoline vehicles to reduce fuel consumption. These include: engine downsizing, cylinder deactivation, LED headlights, improved air conditioning, advanced transmissions, low rolling-resistance tyres, stop/start technology and brake energy recuperation – to name just a few.

FE improvement derived from next generation lubricant technology is also very attractive to OEMs because it is relatively easy and inexpensive to implement compared with these hardware changes.

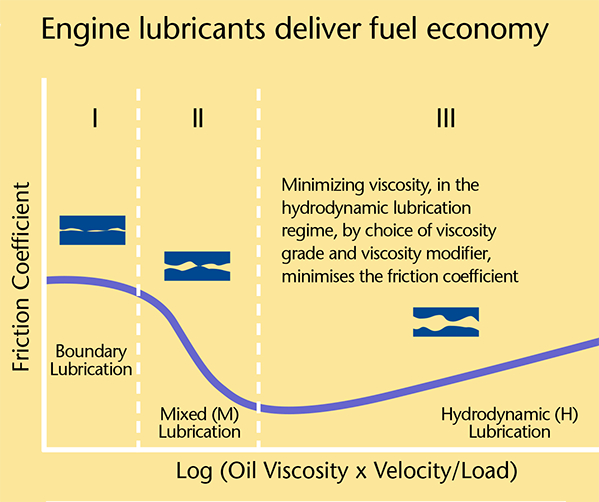

This has driven the trend towards lower viscosity oils and formulations that use innovative new additive technology to deliver increased FE.

Clearly in the quest for lubricant derived FE it is essential to balance the need for reduced fuel consumption with the need to meet the most challenging OEM and industry specifications to maintain excellent engine durability.

In the past three decades, advances in additive and lubricant technology and the use of lighter viscosity grades have delivered significant FE improvements. We have seen a progressive move in the industry to SAE 0W-20 oils and even lower.

However, the viscosity must be high enough so that the oil can form a continuous film at high temperatures for wear protection. While there is still some potential to achieve FE improvements by formulating at lower viscosities, new step-out additive components are increasingly essential.

The two most popular viscosity modifiers are Olefin copolymers (OCP) and hydrogenated styrene diene (HSD) polymers. However, because both of these polymers expand at low temperatures, they contribute more to the viscosity at low temperature than at high - not what you want for a fuel economy oil.

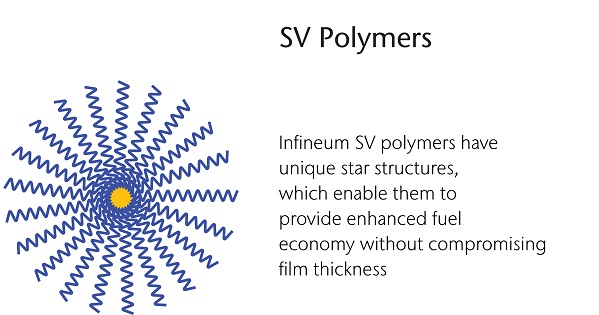

Infineum decided to try and change the way the HSD star polymer, typically used in top tier oils, contributes to viscosity at lower temperatures.

The resulting new Infineum SV viscosity modifier needed to minimise lubricant viscosity at lower temperatures, meet industry performance standards, have excellent shear stability at a low treat rate, retain low temperature performance and provide viscosity control at high temperatures.

The star structure of the Infineum SV polymer was re-designed so that it contracts when temperatures are reduced to below 120ºC. This results in an oil that has a lower viscosity during the warm up phases of the engine.

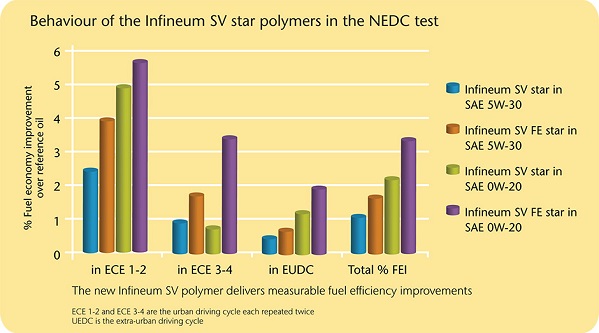

However, the real test is whether this viscometric credit leads to a measurable reduction in fuel consumption. In Europe, the key fuel economy test is the New European Driving Cycle (NEDC) Test, which is used to assess the emission levels of car engines to obtain government approvals.

During the first two phases of this test the car is run on an urban cycle while the test oil warms up from about 20°C to its operating temperature. For oils containing fuel economy enhancing VMs we would expect to see credits in these first two phases.

An SAE 5W-30 oil formulated with the new Infineum SV star polymer gave an excellent boost in fuel efficiency in the first two phases, and gave a total improvement in FE of 1.7% over the reference oil, and when formulated in SAE 0W-20 a 3% improvement in FE was observed.

However, fuel efficiency improvement is not enough – the oil must also meet the full range of industry performance requirements to ensure engine durability. In a range of severe tests for properties including shear stability, deposits, sludge and oxidation, the modified polymer delivered performance typical for a conventional premium HSD star viscosity modifier.

The advantages of Infineum SV VMs extend way beyond FE and performance requirements.

The new VM also delivers benefits in formulation choice, logistics, and product consistency by providing flexibility in base stock and pour point depressant selection, better low temperature properties in fresh and aged oils, formulation and logistics savings and outstanding product consistency.

The new Infineum SV star technology, launched at the Fuels and Lubes Asia Conference this spring, delivers measurable FE improvements in test cycles that have a low temperature phase, addressing OEMs’ requirements for emissions reduction.

At the same time, it retains all the other advantages of Infineum SV VMs, which make them the viscosity modifiers of choice for top tier formulations globally.

Infineum SV viscosity modifiers offer many benefits, which complement our detergent inhibitor technology to deliver enhanced performance in long drain and premium applications. Because our VMs retain their properties throughout the life of the oil they deliver benefits including:

Sign up to receive monthly updates via email