Commercial vehicles

ACEA HD Sequences released

22 January 2025

Please note this article was published in December 2013 and the facts and opinions expressed may no longer be valid.

12 December 2013

Contributing to the fuel efficiency of future trucks

With North America determined to increase its energy independence and cut greenhouse gas emissions, the US DOE is supporting a number of programmes designed to improve the efficient use of energy in the transport sector. Insight talks to MIT’s Dr Victor Wong and Infineum Global Engine Lubricant Advisor, Dr Jai Bansal about their involvement in one such programme.

Long-haul Class 8 trucks are estimated to consume some 16% of all the fuel used in the US, which makes them a prime target for efficiency improvements. One initiative, which aims to develop technologies that will improve the efficient use of energy in these vehicles, is ‘SuperTruck’.

Co-funded by the US Department of Energy (DOE) and industry to the tune of $270 million, the SuperTruck programme aims to design a heavy-duty Class 8 truck, which demonstrates a 50% improvement in overall freight efficiency measured in ton-miles per gallon.

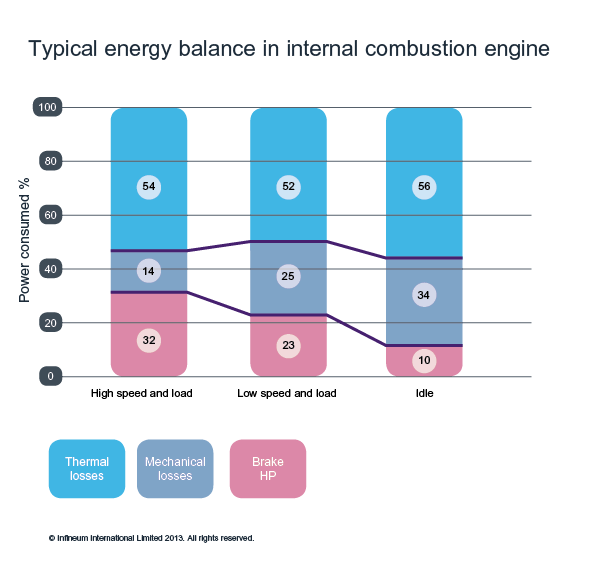

This improvement will be achieved through the application of advanced vehicle system technologies and advanced engine technologies. At least 20% of the improvement will be through the development of an engine capable of achieving 50% Brake Thermal Efficiency (BTE) and up to 30% from vehicle technologies.

As a separate and parallel effort, participants will identify key pathways to achieving the long term goal of developing a 55% efficient BTE heavy-duty diesel engine.

Four teams, headed by companies that make up of more than 75% of the North American Class 8 truck market, Daimler Trucks North America, Navistar, Cummins, and Volvo Technology of America are currently involved. Their focus is to develop and demonstrate cost-effective, system level fuel efficiency technologies by 2015, including:

As improved and more cost-effective manufacturing methods are developed, and market demand for better fuel economy increases, more of the technologies developed in SuperTruck will find their way into Class 8 trucks.

The DOE expects some 80% of these technologies to be seen in the marketplace within the next decade.

However, in the last decade there has been a growing awareness that efforts should also be made to look for fuel economy improvements from sources other than hardware, and increased interest has been directed at the contribution that lubricants can make to the reduction of friction.

“Tremendous efforts have been made over many years to reduce friction via engine component design, component materials and surface characteristics,” says Wong. “But, despite the fact that lubricant properties play an important role in affecting engine friction they have often been considered outside the mix of controllable parameters in development projects, until recently.”

“This was evident in the pioneering research program we carried out at MIT, between 2002-7”, he continues. “We looked at low engine friction technologies, in which lubricants, surface characteristics, and component design were all studied. This work is now being followed up by the current DOE funded lubricant formulation program.”

MIT and Infineum are looking at areas specifically related to lubricant formulation, and assessing lubricant-rheology control as a major strategy in friction reduction. In this latest collaboration the two organisations have been examining a number of factors to gain fuel efficiency via the reduction of mechanical losses, including:

“So far we have looked at only a few lubricant properties, including the viscosity, viscosity index and the shear-thinning characteristics,” explains Bansal. “Going forward, an extended set of design variables including different viscosity modifier polymers and base stocks will be evaluated in relevant test engines.”

The results to date have been very encouraging but both MIT and Infineum feel that there is much more to do.

We asked Dr Wong what challenges he can foresee, and he reminded us that fuel efficiency is not the only thing we need to consider.

“Clearly we must balance fuel economy improvements with wear protection and we understand that recent advances in antiwear technology for low viscosity regimes could mitigate some of the increased boundary lubrication. To ensure wear will not be compromised we have commissioned additional work with Infineum.”

”In addition we recognise, even within the fuel economy arena, that there is a lot of room for further improvement. For example, significant fuel efficiencies can be gained by controlling the lubricant properties to location-specific optimal values at various critical locations in the engine.”

“However, it will be a big challenge to attempt to control lubricant properties locally in the engine, where different temperatures, shear rates, and mechanical loads require different lubricant properties. From an engine-engineering standpoint, this could be achieved via in-engine control of the oil temperature and thus the oil viscosity.”

The real question that remains is whether this can be achieved more cost effectively through lubricant redesign, without the need for new engine technologies.

Controlling lubricant properties locally in the engine could be achieved via in-engine control of the oil temperature and thus the oil viscosity

Controlling lubricant properties locally in the engine could be achieved via in-engine control of the oil temperature and thus the oil viscosity

Dr Bansal agrees with Dr Wong’s assessment of the challenges ahead. “Although we have not exhausted our bag of tricks to influence location specific lubricant properties in the engine, it will take time to design and test these more step-out approaches.”

The next step in the project for MIT and Infineum is to examine more closely the different roles that other variables, such as other additive formulations and lubricant rheology, can play in optimising both friction and wear.

Sign up to receive monthly updates via email