Marine engines

OEMs outline challenges ahead

08 December 2025

Please note this article was published in May 2013 and the facts and opinions expressed may no longer be valid.

06 May 2013

Setting the new technology benchmark

To design a system oil package with performance equal to or better than those currently available Infineum recently undertook an extensive bench testing exercise. See Tien Tan, Infineum Marine Deployment Technologist, talks about the findings and future developments.

System oils, or circulating oils, lubricate the crankcase in large slow speed two-stroke marine diesel engines typically used in container ships.

The system oil does not need to lubricate the piston rings and cylinder liners in these engines because a separate oncethrough marine diesel cylinder lubricant (MDCL) is used for this purpose.

System oils lubricate the crankcase in large slow

System oils lubricate the crankcase in large slow The requirements for system oils are therefore similar but somewhat simpler than normal trunk piston engine oils (TPEO), which are used to lubricate medium speed four-stroke marine diesel engines. This means that in many cases system oil packages are based on TPEO, which is down-treated to meet alkalinity requirements and boosted with antiwear additives and/or corrosion inhibitors to compensate for the down-treat.

MAN Diesel & Turbo (MAN) dominates the large slow speed two-stroke marine diesel engine market, holding over 80% market share. Wärtsilä and Japan-based Mitsubishi Heavy Industries are also key OEM players.

Unlike the automotive industry, where performance standards for lubricants are published by industry bodies (e.g. API, ACEA or JASO), each marine diesel engine OEM defines the performance requirements for lubricants for use in their engines.

System oil performance is usually proven in an OEM-supervised field trial, which, if successful, leads to the issuance of a ‘No Objection Letter’ and a listing in the OEM validated oil list.

However, because field trials are costly, (more than US $150,000), and time consuming (taking 4,000 hours or at least nine months), and are run in a fully operational ship, bench and engine tests are run in advance to provide some level of confidence in the candidate oil.

MAN does not have a prescribed list of bench tests, though it does describe in some detail the functions that the lubricant should have.

Wärtsilä has a published procedure for oil approvals and the document describes the test requirements for system oil. However, it does not specify limits except for the FZG load test. This test is of particular importance to the OEM for its RT-Flex engines since they use a series of gears to turn the camshaft driving the fuel pumps for the common rail system.

Mitsubishi Heavy Industries does not have a procedure in place for system oil – lubricant performance is described without specifying test methods or assigning limits.

To support the development of a new system oil it is essential to understand the level of performance required or deemed acceptable in the market.

Infineum additive packages have been used as system oils for many years, but very little is known about their performance relative to other system oils in the market.

In order to determine the relative performance of system oils Infineum formulated various candidate oils of identical SAE viscosity grade and BN, which were blended using different Infineum marine additive packages in Group I base oils.

The six Infineum candidates chosen for this benchmarking exercise include recommendations based on complex detergents and salicylates. These were directly compared against commercially available oils marketed by the five major marine lubricant suppliers.

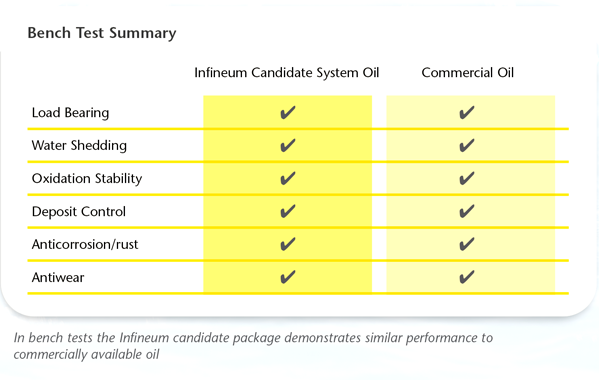

Both the Infineum candidates and the commercial oils were subjected to 12 bench tests under the same operating conditions.

In this benchmarking exercise, which compared off the shelf system oils to those blended using different Infineum additive packages, the Infineum packages demonstrated similar performance to all of the purchased oils, including one that is usually perceived as the market leader.

While the benchmarking exercise was not able to identify the best and worst performers, it helped to identify some components that could be eliminated from the system oil package. It also validated that a down-treated package based on TPEO and boosted with zinc dialkly dithiophosphate (ZDDP) is fit-foruse in system oil applications.

This study has enabled Infineum to assess the merits of various candidate oils and to select the most appropriate to take forward to further engine tests and field trials.

By careful and thorough analysis of the data generated from the wide variety of bench tests Infineum has identified a candidate based on its salicylate technology as the best to proceed to the next phase of the development, which will include treat rate and componentry optimisation.

Also, as Group I base stock supply becomes tight, Infineum is increasingly interested in the development of marine lubricants in Group II base stocks that can give the same or better performance as their Group I counterparts.

Future work will evaluate the suitability of blending the candidate system oil in Group II base stocks, which will give oil marketers and blenders some flexibility in base stock selection.

Sign up to receive monthly updates via email