PC-12

PC-12 on track for 2027

26 August 2025

04 September 2023

Southwest Research Institute on what we know about the test developments

Industry is already busy with the development of the new American Petroleum Institute (API) PC-12 heavy-duty engine oil category. Bob Warden, Diesel Engine Oil Section Manager from Southwest Research Institute (SwRI), talks to Insight about his views on the testing requirements, the work being undertaken and progress being made so far.

As part of SwRI’s Fuels and Lubricant’s Research Division, which is involved in the development of standardised lubricant evaluation test methods for API, OEM and other lubricant specifications, Bob Warden is well placed to provide an update on PC-12 progress. With new category developments there is always a huge amount of test development work and PC-12 is no exception in this regard. New tests or tighter limits are required for certain parameters and, in addition, work must be undertaken on tests that are reaching the end of their useful life. Bob starts by giving us an insight into the test developments for PC-12, where several tests fall into this latter aged category and need to be replaced or eliminated.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

The roller follower wear tests and the [Caterpillar] 1N have been in use since the mid-nineties as part of the CG category, and at this point are largely redundant with either existing tests or have reached a point where the hardware for them is just not available anymore. These tests are moving out of the category and generally felt to not need an active replacement test need made for it. The Mack T-12 test is going to be moving out of the category, due to a combination of factors. One is the fact that the hardware is going to be limited in its availability and not able to support through the life of the next category, but also the particular phenomena that it was testing for, particularly liner wear, is one that many of the OEMs feel has been largely solved by improvements in material technology and coatings on surfaces such as the rings. So, the Mack T-11 and the Mack T-8 utilise some of the same hardware as the T-12 and is going to require them to be replaced as well due to that availability. There are some ongoing efforts in the industry to replace these tests, support not only the new category, but also the backwards compatibility that they could apply to.

The Mack T-11 test is also reaching the end of its useful life. With Bob acting Chair of the task force looking into replacing it we were keen to get an update on how the replacement activities are progressing.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

Stating that we're just replacing it may be a bit of an oversimplification. As chair of the task force leading these efforts, there's actually three different things that we're trying to do with this test. One is to replace the T-11 level of performance, as well as the backwards compatibility aspect of the T-11 to replace the T-8 test in all the myriad places that it's used in global specifications, OEM specifications and older API limits, and then also to establish a criteria for the PC-12B category at a lower performance level of soot than what the T-11 replacement need is.

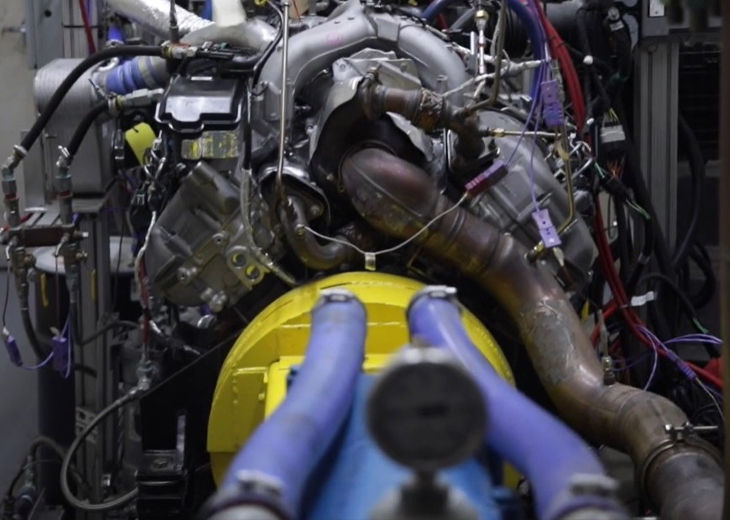

The Cummins ISB test has been selected to replace the Mack T-11 test and the fact it already exists at test labs has accelerated the timing and pace for the test developments. The good news is that the ISB runs for a shorter duration of time and consumes less fuel and uses a smaller engine, reducing the overall cost of the test compared with its predecessors. Fuel choice has been another topic of consideration for PC-12 test developments.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

For something like the replacement of the T-11 it was found that the low 15 ppm sulphur fuel that you could get at a marketplace right now is not suitable for use in that test. It drives severity very mild, and so we have to use a specialised fuel in the 500 ppm sulphur range to make that test work right.

Each test is going to have its own dependency on the fuel. Some are going to be very agnostic to the fuel and, it really doesn't matter what we run in it within limitations where others are going to be extremely sensitive to the fuel and it has to be dialed into a very specific formulation or composition for that test to behave appropriately.

Another factor to consider as engine tests age, and they are moved forward from legacy categories into the PC-12 category, is that the reference oils used in those tests are also getting older. Bob explains the activities underway on the replacement of some of these older reference oils going into PC-12.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

The technologies that they represent are not consistent with what's mainly in the marketplace at this stage of time and need to be updated to reflect something that's going to respond in the way that a more modern oil would. If we see changes in test performance that impact a reference oil that may be from 20 years ago, that doesn't necessarily mean that it's going to respond the same way to a candidate oil that's being run today. As we're moving into the lower viscosity range, there's also a need to establish these reference oils in that viscosity range to ensure that we're setting severity adjustments and other corrections based on where a candidate oil is performing and not something that will likely never run in that engine.

One of the specific areas of work here has been on the Caterpillar C13 test that needs to be altered to allow low viscosity oils to be tested.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

There are some signs that some of the existing tests, particularly the Caterpillar deposit tests, may struggle with the low oil pressures resulting from running a 0W-20 product. We are making some active changes in the ECM to allow the engine to not derate when it sees the lower oil pressure that would have historically, when running a 15W-40, indicated a problem with the engine. But when you're using a modern lower viscosity oil is just the result in pressure that you'll see in the engine under normal operation.

In addition to the activities around test replacement and elimination, there are also some new tests that will be included in PC-12. One is the Daimler DD13 scuffing test, and we were keen to hear Bob’s thoughts on what needs doing here.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

This test isn't actually a new test at this point, but it's been an ASTM method for quite a few years now, residing in the Detroit and Daimler internal specifications. It just missed the timeline for inclusion in PC 11, but still became a full ASTM test method and has conducted its precision matrix. What hasn't been conducted are any efforts to establish a BOI or VGRA guideline or expansion of test precision down into some of the lower viscosity grades that we're currently looking at for PC 12.

Work is also underway on the Mack T-8 and T-11 replacement. This test activity is expected to be used to fill multiple voids left by the these tests, which are approaching their end-of-life. Here again the use of the familiar Cummins ISB platform has helped to accelerate the development timeline versus starting with a new engine platform and control strategy that would need to have been brought into various labs across the industry.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

The second effort underway is the T-8 and T-11 replacement. This is lumped into the soot and viscosity test and is currently an ongoing effort across the industry. For the last year or so, there's been data getting generated showing that performance levels, at least for something like the T-11 reference oil, has been very consistent. We've had to make some modifications and changes to conditions such as duration and sooting rate to dial the severity in where it needs to be. There'll always be some differences in test appetite on different chemistries as we move from one platform to another. It will be an entirely new test, so it will require both a precision matrix as well as any BOI or VGRA guidelines to be established.

Another test that has seen significant work has been the development of the Ford 6.7 litre valve train wear test But, as Bob explains, there have been many challenges to overcome. And, with Ford no longer part of the EMA, this test development for PC-12 has ceased and the test is now likely to remain only as part of Ford’s own specification.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

This test has been in the process of development for quite a few years now, but currently has some challenges due to hardware. We're attempting to move from the 2019 and earlier engine platform, which had aluminium pistons to a more modern design that Ford started using in 2020 with the steel piston in the bottom end of the engine. This is largely due to availability and trying to ensure that we're running the precision matrix and any test establishment runs on something that's going to be sustainable out for the next 15 to 20 years.

In the quest for fuel economy improvement, heavy-duty engine oils have been trending to lower viscosity grades. In 2000 the market was dominated by SAE 15W-40 grades with monogrades still holding more than a 20% share. While SAE 15W-40 grades still dominate, as Bob explains, this picture is changing and, as viscosities trend lighter, new reference oils will be needed to ensure tests that were developed in the PC-10 timeframe with SAE 15W-40 reference oils are suitable for use with new lower viscosity fluids.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

Today the use of a 10W-30 is highly prevalent in the HD environment with most of the 15W-40 usage happening in the off-road sector. As we see a movement over the next five years towards meeting tighter and tighter emissions requirements, we expect there to start being more penetration of XW-20 viscosity grades.

So, reference oils that would be needed for PC-12 include ones that are going to be operating in that lower viscosity regime Either say an XW-20 or even a lower viscosity XW-30, similar to what the FA-4 category was. We need to be moving in that direction and away from the prevalency of 15W-40 reference oils that many of the existing tests utilise.

To help support this move into the lower viscosity range. The industry really needs to be investing in running these new reference oils and establishing precision based on them, not just assuming that the precision levels of the higher viscosity grades are going to transition over.

In addition to all the activity already mentioned there are other items of interest that are arising in the development of the new PC-12 category including changes to Volvo T-13 test limits, evaluation of seal materials and changes to the limits for sulphated ash, phosphorus and sulphur (SAPS).

Bob Warden, SwRI, Diesel Engine Oil Section Manager

The adjustment of the anticipated limits of the Volvo T 13 from the initial API limits set during the CK-4 / FA-4 development down to the limits utilised in Volvo's VDS 4.5 specification. This includes a restriction on the IR Peak Height and the KV40 well below what they are today and may require a change in how we look at the severity adjustment set at the current reference oil limits. Another item of interest is the possible inclusion of other seal materials that are being evaluated to align the API and ACEA specifications. And the last item is a changing of the chemical box to help improve aftertreatment durability and extend the useful life and warranty claims for OEMs.

So chemical limits for PC-12 are anticipated to be lower than they were for the CK-4 and FA-4 categories for sulphur and phosphorus. The ash content of the oil is one area that OEMs seem to be aligning on, falling down at the 0.9% range, below what ACEA in the API specifications currently allow. For many of the OEMs, this reduction in phosphorus is in an effort to ensure the longer duration life of their aftertreatment systems. However, it comes with the trade off, placing a lower chemical box around what can be in the oil restricts, formulating spaces that the lubricant companies are allowed to operate in and takes out some components that were put in the engine for very good reasons, such as wear protection and detergency. There's going to be long-term tradeoff between the durability of the internal components and the survivability of the aftertreatment that OEMs are going to have to balance.

Finally, with sustainability high on the agenda for commercial vehicle, fuels, lubricants and additives manufacturers, we wanted to gauge Bob’s opinion on how sustainability is being considered in PC-12 developments.

Bob Warden, SwRI, Diesel Engine Oil Section Manager

Sustainability is definitely in the forefront of a lot of minds as we're going through the PC 12 development process. Here are just a few examples. First being the introduction of the lower viscosity fluids for each of those products that makes it to the marketplace, the anticipated fuel savings over time is going to far outweigh what they went through, through the development efforts. Second, in the redevelopment of the T 11 into a smaller platform that burns significantly less fuel, that's a direct opportunity for us to reduce the carbon footprint of qualifying a product.

Every gallon of fuel that we burn in the development of the category or the qualification of lubricants is something that we need to be mindful of. Anytime that we can remove that fuel from the process that improves the carbon footprint of the industry as a whole.

The PC-12 category is continuing to evolve, bringing new challenges to the formulation of heavy-duty lubricants, sign up here to receive our regular updates on its progress.

Sign up to receive monthly updates via email